Why does the mining industry need water treatment equipment?

Its wide selection in petroleum metals industry, mainly fossil fuel such as oil, gas, coal and more. In the material treatment stage, the main goal is to ensure the purity of the raw materials, stability and usability, through pre-treatment facilities, such as pasteurization, water loss, crack and so on, Improve the material's active reaction. The production process and the features of the mining industry pertaining to a variety of aspects, including selection and material processing, reaction and control process, separation and pure technology, catalysts application, Switch and use energy, safe and environmental production, innovation and optimization technology and integrated production process. By optimization and finishing these aspects, you can improve the efficiency and production quality of the metal mining industry, develop sustainably.

Mining Metallurgy Industry Solutions

1. Evaporation device: such as MVR evaporation device, forced circulation device, low-temperature evaporation device, and multi effect evaporation device

And in production

The evaporation equipment in the mining industry is mainly used for wastewater treatment, hydrogen metal processing optimization, and resource recovery. Specific applications include:

(a) Wastewater and Zero Discharge Treatment (ZLD)

High salt wastewater treatment: Wastewater from mining and metallurgical processes usually contains high concentrations of inorganic salts and heavy metal ions, and direct discharge can cause serious environmental pollution. Evaporation devices (such as evaporators, steam, and compressed respiration (MVR)) can evaporate water from wastewater, producing pure and pure water. Concentrates can be further concentrated or extracted, and pure water can be reused in production processes or standard waste to reduce wastewater and resource consumption.

Acid and potassium wastewater treatment: For wastewater containing acid and potassium, steam equipment can effectively concentrate the acid and potassium components in the wastewater, facilitating subsequent neutralization or recovery of acid and potassium, reducing the cost of purchasing new acid and potassium, and reducing waste volume.

(b) Optimizing hydrogen metal processing technology

Concentrated extraction: In wet metallurgical processes, in order to improve the efficiency of subsequent processes such as extraction, sedimentation, or charge, it is sometimes necessary to concentrate the detergent. The evaporation device can quickly and efficiently concentrate valuable metal ions in detergents, reducing energy and subsequent processing costs.

Solvent recovery: When using hydrogen metering processes (such as solvent extraction), the evaporation device can be used to recover and reuse solvents such as alcohols, amines, etc., reducing solvent consumption, processing costs, and environmental impact.

(iii) Resource recovery and by-product treatment

By-products of crystal salt production: Some hydrogen metal processes produce salt containing by-products, such as sulfates, chlorine, etc. The evaporation device can evaporate these salt solutions to produce pure and reusable salt products.

Concentration and recovery of heavy metal salts: Wastewater contains heavy metal ions or by-products, and steam equipment can concentrate heavy metal salts in it, thereby recovering heavy metal resources through chemical sediment, storing electricity, reducing environmental pollution risks, and increasing economic benefits.

(4) Save energy and reduce emissions

Waste heat: Waste heat, cold water vapor, or condensate generated during mining and metallurgical processes can be used as a heat source for evaporation devices, saving energy and reducing total energy consumption.

Reducing solid waste: Treating wastewater through evaporation equipment can greatly reduce the generation of solid waste (such as residue evaporation), lower the cost of solid waste treatment, and lower environmental pressure.

(5) Environmental restoration and historical management

Waste treatment: For high residual salt mineral waste and heavy metal waste, steam equipment can be used as one of the management technologies to safely dispose of waste or recycle resources by evaporating waste concentrate, supporting mine maintenance environment.

Technical Principles

MVR evaporator: The evaporator reuses the energy generated by its own secondary steam to reduce the demand for external energy. The operation process of MVR is to compress steam in the refrigeration compressor, increase temperature, pressure, and temperature, and then enter the heating and condensing system to utilize the potential temperature of steam. Except for the drive start, no steam is discharged from the second steam of the evaporator during the entire evaporation process. It is compressed by the compressor, causing an increase in pressure and temperature. The steam is then sent to the heating chamber to maintain liquid boiling.

Forced evaporation device circulation: The circulation of solution in the device mainly relies on the forced flow generated by external forces. The cycle speed is usually between 1.5 and 3.5 meters per second. Thermal energy and production capacity. The raw material liquid is pumped upwards from the bottom by a circulating pump, which flows upwards in the pipeline of the heating chamber. The mixture of steam and liquid foam enters the evaporation chamber and is separated. The steam is discharged from the top, the blocked liquid drops, is sucked into the conical bottom by the circulating pump, and then enters the heating pipe for further circulation. It has heat transfer coefficient, salt resistance, soil resistance, strong adaptability, and is easy to clean. Suitable for industries such as scale, crystal, temperature sensitive (low temperature), high concentration, and high viscosity, including chemically insoluble solids, food, pharmaceuticals, environmental protection technology, and evaporation recovery.

Cold evaporator: The temperature of the cold evaporator refers to the normal operation of woodworking evaporation at 35 to 50 ℃. After arriving at Ye Wei, solidification is carried out in each bucket of water, and the pump works to generate a vacuum. She is operated by the automatic water and evaporator - YaSuji, which generates heat to evaporate and heat the wastewater. The wastewater is in a zero vacuum state, and the temperature of the wastewater rises to around 30 ℃. The wastewater begins to evaporate before completion. After evaporation, YaSuJi sets the temperature to 35-40 ℃ and compresses the local area network with cold water to generate temperature. While the water rapidly evaporates, it cools the local area network through an expansion valve and wants to operate the heat absorption system after evaporation, rising to cold steam. The odor decomposition solution is soluble in spring water, sturdy and durable, and can be compressed and absorbed by YaSuJi ZhiRe to absorb heat and cold. Simply reheat the wastewater. If the bubble is detected by the sensor during the evaporation process, the defoamer will automatically add defoamer. After one cycle is completed, the concentrate will be discharged (the cycle time can be set). After the evaporation cycle is completed, the compression pump stops working, focuses on the open pneumatic valve tube, pressurizes and evaporates, and focuses the hydraulic pressure on the barrel.

What kind of results can we achieve

Our company's evaporator can reach a concentration of 5-100 times under different water quality conditions, making it more energy-efficient, easy to adapt, highly automated, environmentally safe and stable. It has been widely used in industries such as chemical, pharmaceutical, food, and environmental fields.

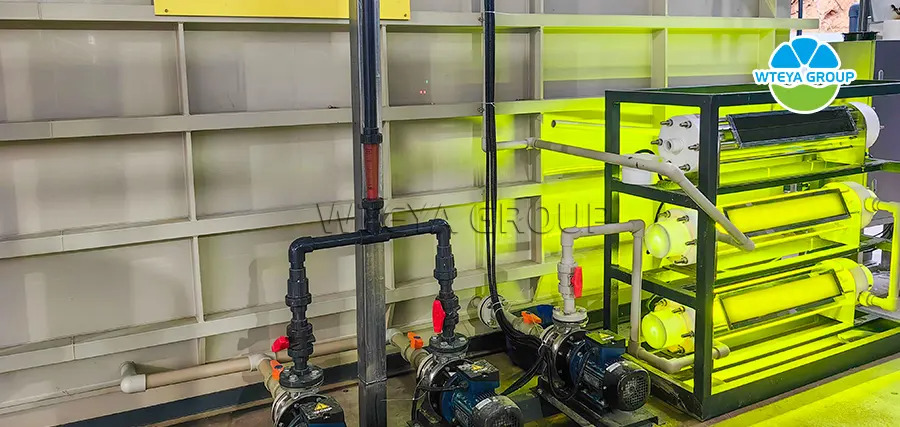

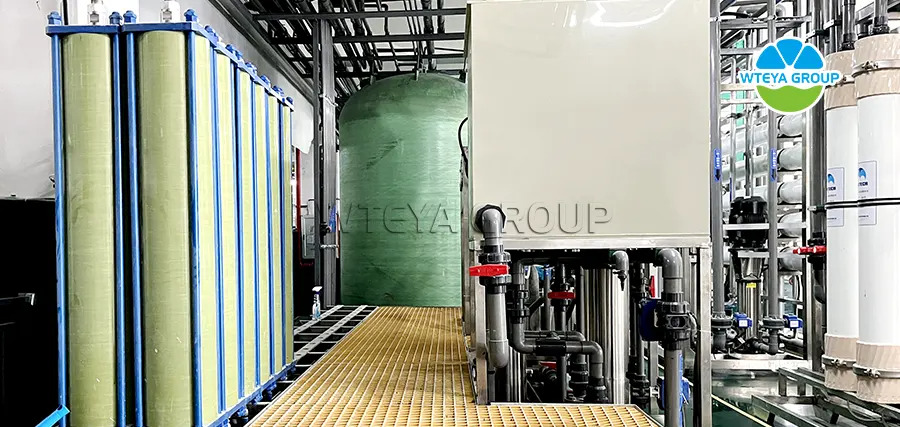

2. Diaphragm separation equipment: DTRO, STRTO, NF, etc

And in production

The application of thin film separation technology in the mining metal industry is reflected in the following aspects:

(a) Concentration and treatment of mineral water

Small capacity concentrate: Traditional concentration methods may be ineffective for small capacities after grinding. By using ceramic membrane separation technology, such as membranes, mineral water can be effectively focused and the concentration of mineral water can be increased to the level required by the next process, especially suitable for small ore processing in low resource mining.

Toxic element removal: Membrane separation technology can selectively remove toxic or attached elements, such as heavy metal ions, by selecting special membrane materials and adjusting operating conditions to purify minerals and improve resource utilization efficiency.

(b) Optimizing hydrogen metal processing technology

Leaching detergent solution and accumulating metal ions: in the process of hydrometallurgy in the metallurgical process, the leaching membrane separated from the solution can be deeply cleaned. "The existing technology removes spots, gel and some silver impurities. Through the nak filter, it must have waterproof measures to wait, and the metal ion redemption rack (such as copper, nickel, zinc, gold, silver, etc.) is sealed into the accumulation, reducing the weight and cost of subsequent extraction, precipitation or ionosphere processes.

Agent complexes, acid reactants, and regenerated potassium: Compounds of agents, acids, potassium, and other reactants used in processing or sedimentation can be used through separation and recovery equipment to reduce chemical consumption, production costs, and environmental impact.

(iii) Wastewater treatment and resource recovery

Heavy metal waste treatment: Waste containing heavy metals in the metallurgical process can be effectively prevented from heavy metal ions, qualified waste, or recovered heavy metal resources through membrane separation technologies (such as reverse osmosis and electrically controlled membranes).

Sulfuric acid and alkali recovery: In the process of hydrogen metallization, sulfuric acid and alkali are commonly used as reagents or to adjust the pH value of reagents. Thin film separation devices can effectively recover sulfuric acid and potassium from waste, achieve acid balance and closed management of potassium, reduce the cost of purchasing new acid and potassium, and reduce the amount of waste.

Waste and by-products

Tailings sludge dewatering: By using filter membranes or ceramic membranes for deep dewatering of tailings, waste accumulation can be greatly reduced, soil occupation can be reduced, potential environmental risks can be minimized to the greatest extent, and it is beneficial for the reuse of valuable components in waste.

Pure by-products and value-added products: by-products in hydrogen metal processing, such as sulfides, sulfates, etc., can be separated and purified using refined membrane separation technology to improve product market value and maximize resource utilization.

Technical Principles

This process uses special membranes to separate components from liquid or gas mixtures. The basic principle of this technology is based on the differences in the speed and ability of different components passing through the membrane, which can be determined by the characteristics of the components, the characteristics of the membrane, the concentration differences on both sides of the membrane, pressure gradients, potential gradients or steam, or various factors. Membrane separation methods include microfiltration, ultrafiltration, filtration, reverse osmosis, and electrofiltration, each of which is suitable for different separation needs. For example, microfiltration and ultrafiltration filter molecules or solutions of different sizes based on the pore size of the membrane; Reverse osmosis refers to the pressure higher than the osmotic pressure of the solution, causing the solvent to pass through the membrane and block the solution; Electrodialysis is the selective utilization of ions in a solution using ion exchange membranes under the action of an electric field.

What kind of results can we achieve

Membrane separation technology usually has the characteristics of low energy and low operating temperature. Compared with traditional separation methods, it can significantly reduce energy consumption and greenhouse gas emissions. In addition, indirectly reducing energy demand and carbon footprint through resource recycling and reducing wastewater emissions. In the mining and metallurgical industry, separation membrane technology can not only be used in Guangjiang, which is a process for optimizing the wet metallurgical industry, treating wastewater with recycled resources, but also in Weiguang treatment, environmental monitoring, energy conservation, and reducing multiple standby emissions. It is crucial to improve the shown resources, reduce production costs, reduce green environmental pollution, and achieve sustainable development.

3. ECC oxidation equipment:

And in production

ECC catalysts are mainly used in the mining industry for metal removal of high salt liquid organic compounds. It can also kill microorganisms in water, ensure pure liquid water, and ensure the normal operation of equipment.

Technical Principles

ECC catalytic oxidation technology is a new technology developed by the company, which uses catalysts to promote the oxidation reaction between organic pollutants and oxides (such as oxygen, ozone, hydrogen peroxide, etc.) under specific conditions. The final product is harmless or low toxic, achieving pollutant removal effect. The oxidation catalytic equipment varies according to different applications and objects, using different oxidants, catalysts, and reaction conditions to meet practical needs.

What kind of results can we achieve

The efficiency of company type organic removal products (CODcr) exceeds 80%, and some can exceed 95%. It can also significantly reduce the heating temperature of the reactor, the probability of steam device bubbles, and system membrane fouling.