Are You Facing These Pain Points?

We understand the core challenges of fertilizer production.

1

High Energy Consumption

Traditional evaporation processes are energy-intensive, leading to soaring steam costs that erode profits.

2

Unstable System Operation

Equipment is prone to scaling and clogging, causing frequent shutdowns and affecting production continuity.

3

Immense Environmental Pressure

High-salinity wastewater is difficult to treat, leading to non-compliance and risks of heavy fines or shutdowns.

4

Low Automation Level

Reliance on manual operation increases labor intensity and lacks precise parameter control for fine management.

Core Advantages of the WTEYA System

We provide more than just equipment; we are value creators.

High Efficiency & Energy Saving

Utilizing MVR/multi-effect evaporation, power consumption is as low as 15-70 kW·h per ton of water, significantly reducing costs.

Stable & Reliable

Professional anti-scaling and anti-clogging designs ensure long-term stable operation and continuous production.

Intelligent Control

Fully automatic PLC control with one-key start/stop and real-time monitoring reduces manual intervention.

Tailor-Made

We provide integrated custom services from design to commissioning based on material properties and client needs.

Excellent Quality

Strict quality control with core components from renowned international brands ensures superior performance.

Green & Eco-Friendly

Achieve zero wastewater discharge and resource recovery, complying with environmental policies for sustainable development.

Exquisite Craftsmanship · Superior Quality

Every component is meticulously designed and rigorously quality-controlled to ensure the long-term stable operation of the system.

Choosing WTEYA means choosing professionalism, reliability, and peace of mind. We are committed to being your most trusted partner, jointly promoting technological progress and green development in the fertilizer industry.

Two Core Applications, Spanning the Entire Process

From raw material concentration to wastewater reuse, we provide comprehensive technical support.

Solution Concentration & Crystallization

In fertilizer production (e.g., ammonium sulfate, ammonium chloride), evaporation is key to obtaining qualified crystalline products. Our system can:

Wastewater Treatment & Resource Recovery

Fertilizer production generates high-salinity, high-COD wastewater. Our solution is committed to:

Typical Wastewater Treatment Process Flow

A scientifically rigorous process design is the guarantee for the efficient and stable operation of the system.

Core Equipment · Precision Manufacturing

We offer various types of evaporators and crystallizers to meet the specific needs of different working conditions.

MVR Evaporator

Mechanical Vapor Recompression (MVR) evaporators use a compressor to increase the temperature of secondary steam, which is then recycled as a heat source, eliminating the need for live steam. It is one of the most energy-efficient evaporation technologies, especially suitable for low evaporation rates.

Multi-Effect Evaporator

Multi-effect evaporation connects several evaporators in series. The secondary steam from the previous effect is used as the heat source for the next, making cascading use of thermal energy. It is cost-effective and suitable for large processing volumes and wide concentration ranges.

Forced Circulation Crystallizer

This system uses a circulation pump to force material between the heating and crystallization chambers, effectively preventing scaling on heat exchange surfaces. It is ideal for high-viscosity, scaling-prone materials and allows for controlled crystal size.

Rising/Falling Film Evaporator

This evaporator combines the advantages of both rising and falling film types. The material has a short residence time in the tubes, leading to high heat transfer efficiency. It is particularly suitable for heat-sensitive, foaming materials at lower concentrations.

Wide Range of Application Fields

Our technology and services extend beyond the fertilizer industry, covering many related fields.

Compound Fertilizer Production

Coal Chemical Industry

Salt Chemical Industry

Environmental Protection Industry

Landfill Leachate

Other Chemical Fields

Started in 2009, we are an environmental protection technology enterprise integrating R&D, production, sales and installation.

WTEYA Environmental Technology Co., Ltd. is a group company headquartered in Tianan Cyber City, Dongguan City, Guangdong Province. We are committed to providing the world's leading intelligent fluid equipment, with advanced technology and high-quality service, we have won unanimous praise from more than 1,000 customers.

Certifications & Technical Patents

Over 100+ honors showcasing our technical strength and industry recognition.

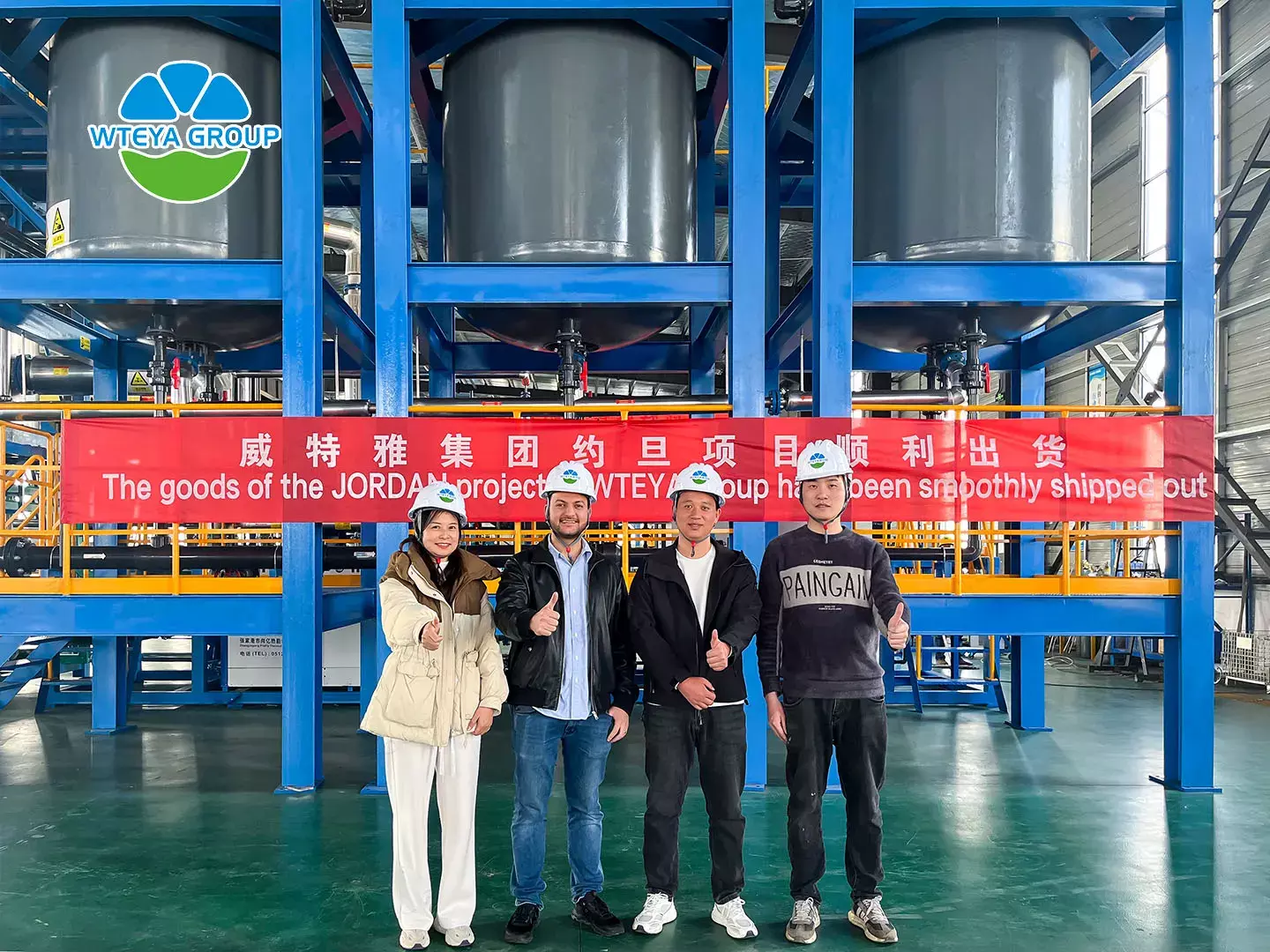

Customer Trust & Collaboration

Growing together with over a thousand clients worldwide.