Understanding the Rare Earth Production Process

From raw ore to finished product, each stage presents unique wastewater

challenges and opportunities for resource recovery.

Mining & Beneficiation

Raw ore is extracted and then crushed, ground, and physically separated to concentrate the rare earth minerals.

Smelting & Separation

The concentrate is chemically treated with strong acids or alkalis, followed by complex solvent extraction to separate individual elements.

Purification & Refining

Separated elements undergo further purification through processes like precipitation and calcination to produce high-purity rare earth oxides.

Processing & Forming

High-purity materials are processed into final products like alloys, magnets, and powders through cutting, grinding, and polishing.

Are You Facing These Wastewater Challenges?

We understand the complex issues you face in your operations.

1

Strict Regulations

Tightening discharge standards create immense compliance pressure, risking fines or even shutdowns.

2

High Treatment Costs

Traditional methods involve high chemical and energy consumption, leading to excessive operational expenses.

3

Complex Composition

High salinity, acidity, and pollutant concentrations make conventional treatment methods ineffective.

4

Low Recovery Rate

Valuable rare earth elements in wastewater are often lost, causing resource waste and economic loss.

Targeted Solutions for Different Wastewater Types

We understand that not all wastewater is created equal. Our solutions are tailored to the specific characteristics of each stream.

1. Beneficiation Wastewater

Characteristics:

- High concentration of suspended solids (SS) and turbidity.

- Contains flotation agents and other chemical additives.

- Relatively low salinity compared to other streams.

Recommended Process Flow:

2. Decomposition Wastewater

Characteristics:

- Extreme pH levels (highly acidic or alkaline).

- High salinity, typically from ammonium chloride or sulfate.

- Contains dissolved rare earth ions and some heavy metals.

Recommended Process Flow:

3. Extraction / Ion Exchange Wastewater

Characteristics:

- Extremely high salinity (>100,000 mg/L).

- High concentration of COD from organic extractants.

- High ammonia nitrogen levels. Contains valuable rare earth ions.

Recommended Process Flow:

4. Refining Wastewater

Characteristics:

- High concentration of salts from precipitation mother liquor.

- May contain residual precipitating agents.

- Lower in organic pollutants compared to extraction wastewater.

Recommended Process Flow:

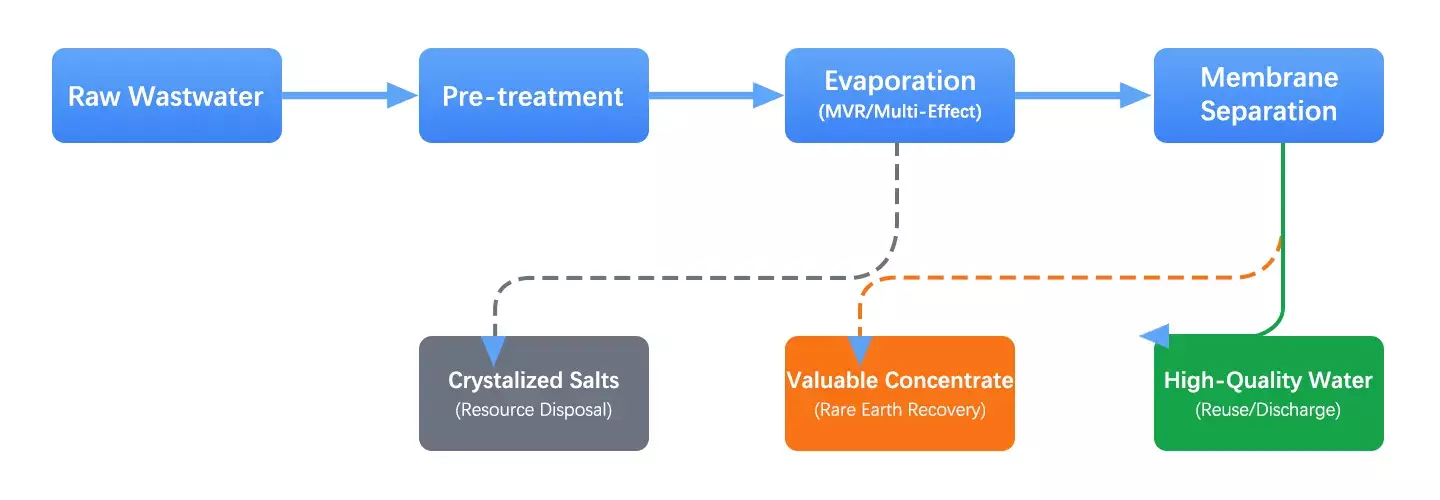

WTEYA's Evaporation-Membrane Hybrid Process:

Your Ultimate Solution

We integrate MVR/Multi-Effect Evaporation with advanced membrane

technology for a highly effective, targeted solution.

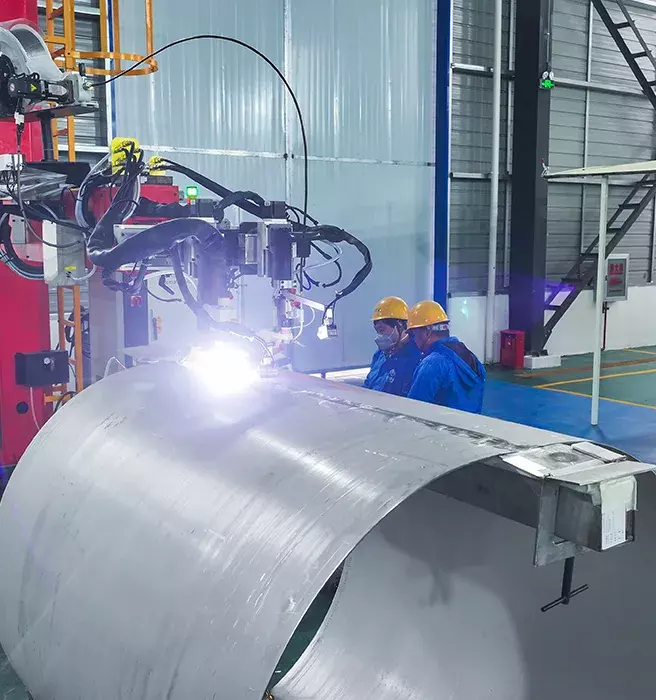

The Two Core Technologies Driving Our Solution

We deeply integrate cutting-edge evaporation and membrane technologies for a synergistic effect.

As the key to volume reduction, our evaporation system utilizes the energy of secondary steam to drastically reduce consumption. It concentrates wastewater over 10 times, efficiently separating salts and pollutants for recovery and further treatment.

- Ultra-Low Energy Consumption: MVR evaporators save over 80% of steam compared to traditional processes.

- High Automation: PLC intelligent control for stable, one-touch operation, minimizing manual intervention.

- Superior Materials: Utilizes special materials like titanium and Hastelloy for long-term operation in corrosive environments.

We use specialized membranes designed for high-salinity wastewater to polish the evaporator condensate. This "micro-sieve" precisely removes dissolved salts and trace pollutants, producing high-quality water for direct reuse.

- Excellent Desalination: Achieves a total salt rejection rate of over 99.5%, ensuring water quality exceeds reuse standards.

- High Fouling Resistance: Specially modified membrane surfaces resist fouling, extending cleaning cycles.

- High System Recovery: Optimized design allows for system water recovery rates of over 90%, maximizing water use.

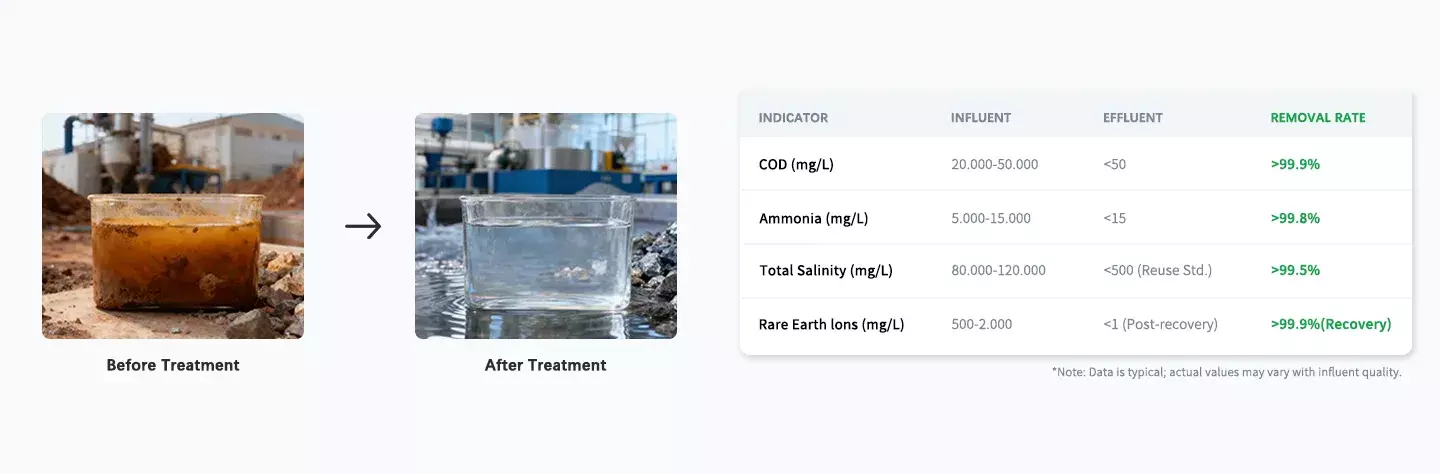

Seeing is Believing: Exceptional Treatment Results

The data speaks for itself. Our process ensures stable, efficient, and compliant wastewater treatment.

Beyond End-of-Pipe Treatment:

Integrated into Key Production Stages

Our technology can be integrated directly into your production process, enabling resource recovery and waste reduction at the source, turning a reactive process into a proactive strategy.

- In-Process Intervention: Intervene after extraction or separation to recover high-value elements before they are lost or contaminated.

- Reduced Load & Costs: Decrease the total pollutant load from the source, reducing the burden and cost on final treatment facilities.

Application Fields: Covering the Entire Industry Chain

We provide precise, customized solutions for various process stages.

Smelting & Separation

Treat high-salinity, acidic wastewater from extraction and crystallization, recovering lanthanide elements.

Permanent Magnets

Handle wastewater from NdFeB magnet production (cutting, grinding, electroplating) for heavy metal removal and water reuse.

Phosphors & Alloys

Solve complex wastewater challenges from producing phosphors and hydrogen storage alloys, ensuring environmental safety.

Polishing & Catalysts

Treat high-TSS, high-COD wastewater from cerium-based polishing powders and cracking catalysts, recovering rare earths.

Optical Glass & Ceramics

Address grinding and cleaning wastewater from processing special optical materials containing La, Ce, and Nd.

Petrochemical Industry

Manage complex wastewater from the production and regeneration of rare earth catalysts, containing oil, salt, and high COD.

WHY CHOOSE US

Expertise, Rooted in 20 Years of Industry Experience

Choosing WTEYA means choosing reliability, efficiency, and long-term value.

20 Years of Experience

We have over two decades of experience in industrial wastewater treatment, with a deep understanding of industry challenges.

Expert Technical Team

Our team, led by PhDs and senior engineers, provides comprehensive support from diagnosis to operation.

Customized Solution

We analyze every wastewater sample to design the most efficient and cost-effective solution for your specific needs.

Outstanding Success Stories

Our expertise and quality are validated by projects with industry-leading companies.

Evaporation Project in Foxconn Group

Waste Liquid Evaporation and Concentration Treatment System Solution, realizing resource utilization and water recycling

Evaporation Project in Rongbai Group

EPC Turnkey Project, including MVR evaporation, concentration and crystallization system for lithium-containing concentrated water

Zero Discharge Project in Kaizhong Precision

600 T/D Advanced Wastewater Treatment & Zero Discharge Engineering Project; Evaporation System Solution

Evaporation Concentration Project in Zhongyi Technology

740 T/D Reclaimed Water Reuse + 5 T/H Copper-Containing Wastewater Evaporation Concentration Equipment Project

Zero Discharge Project in Huilai, Guangdong

600 T/D Waste Liquid Evaporation Concentration & Zero Discharge Treatment Project; Advanced Evaporation System Treatment Solution

Zero Liquid Discharge Project in Inner Mongolia

600 T/D Waste Liquid Evaporation Concentration & Zero Discharge Treatment Project; Advanced Evaporation System Treatment Solution

Started in 2009, we are an environmental protection technology enterprise integrating R&D, production, sales and installation.

WTEYA Environmental Technology Co., Ltd. is a group company headquartered in Tianan Cyber City, Dongguan City, Guangdong Province. We are committed to providing the world's leading intelligent fluid equipment, with advanced technology and high-quality service, we have won unanimous praise from more than 1,000 customers.

Certifications & Technical Patents

Over 100+ honors showcasing our technical strength and industry recognition.

Customer Trust & Collaboration

Growing together with over a thousand clients worldwide.