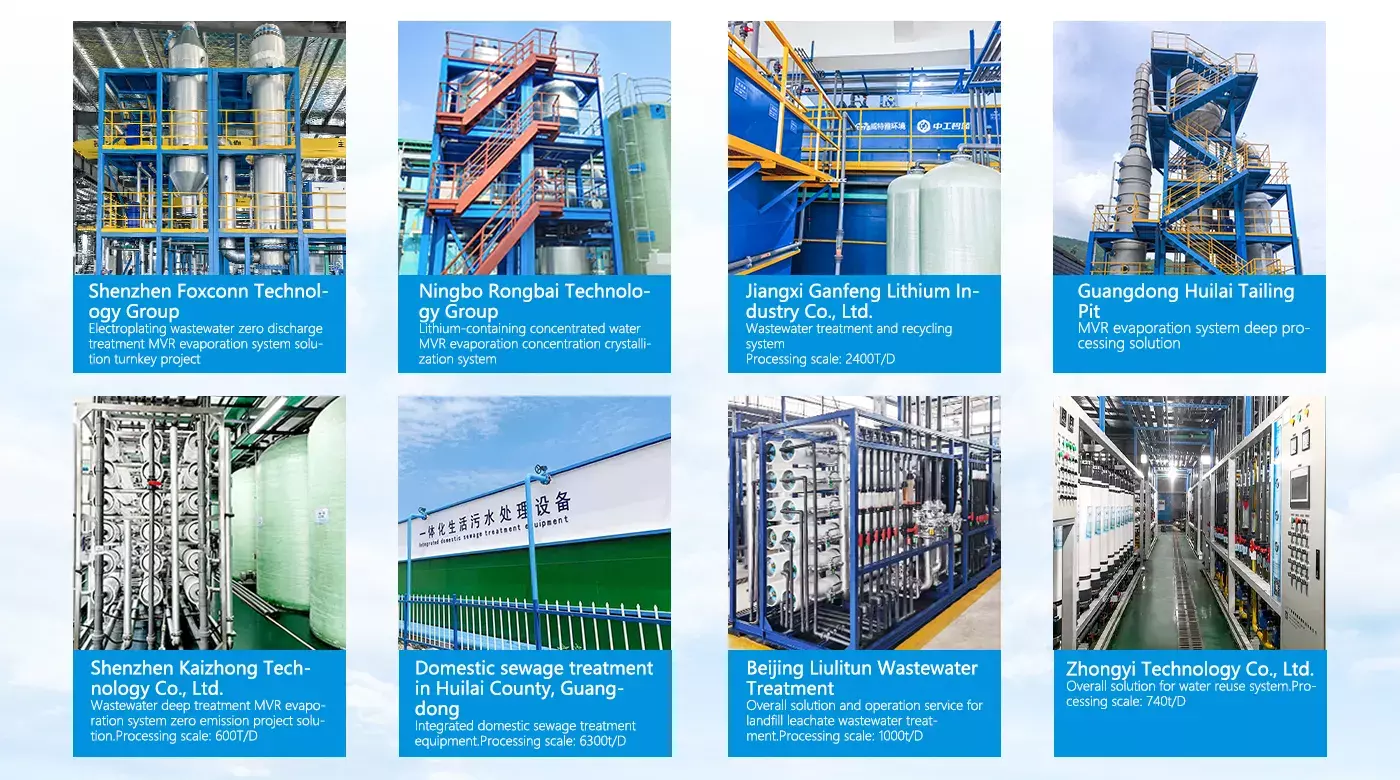

WTEYA is a brand you can trust, with over a decade of extensive experience providing efficient and reliable water treatment solutions to numerous well-known companies worldwide. We have successfully implemented projects for publicly listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with over a hundred project cases earning strong trust and praise from our clients. We support OEM & ODM customization, offering tailored solutions to meet your unique needs.

From Raw Water to Reclaimed Water: How UF Ultrafiltration Systems Enable Full-Process Water Management in Factories

19 Sep, 2025 5:40pm

In industrial manufacturing, the acquisition, utilization, and reuse of water form a complete and complex system. Maximizing water use efficiency has become a key factor for companies seeking cost reduction, operational efficiency, and the implementation of sustainable development strategies. As an effective water treatment technology, UF ultrafiltration (UF Ultra Filter) systems are increasingly being adopted by factories, connecting every stage from raw water treatment to reclaimed water reuse.

1. What is a UF Ultrafiltration System?

UF, or ultrafiltration, is a physical separation technology. It uses membranes with pore sizes ranging from approximately 0.001 to 0.1 microns to remove bacteria, colloids, suspended solids, and some organic matter, while allowing water molecules and small solutes to pass through.

The filtration method offers several advantages:

-

High precision – effectively removes most contaminants.

-

Low energy consumption – suitable for continuous operation.

-

Ease of integration – adaptable to various water sources and industrial needs.

A typical WTEYA UF ultrafiltration system consists of:

-

Raw water pre-treatment (removes large particulates)

-

UF main unit (hollow fiber membrane module)

-

Automatic backwash system (reduces membrane fouling)

-

Chemical dosing system (enhances filtration performance)

These components work together to form an efficient and comprehensive water treatment solution.

2. Raw Water Stage: Laying the Foundation

Many factories source water from surface water, groundwater, or even seawater. Raw water often contains significant amounts of particulates, organic matter, and microorganisms, which can affect downstream equipment if not properly treated.

At this stage, UF systems primarily:

-

Filter suspended solids, iron, manganese, algae, and other common pollutants

-

Reduce contamination risk for downstream RO (reverse osmosis) systems

-

Provide pre-purification for boiler feed water or production use

For example, in a food processing plant, WTEYA’s UF system can reduce the turbidity of surface water to meet subsequent treatment requirements, ensuring both product quality and extended equipment lifespan.

3. Process Water Management: Ensuring Production Stability

Many industries require high-quality water during production. For instance, the electronics industry demands ultrapure water, pharmaceutical manufacturing requires sterile and contaminant-free water, and beverage production emphasizes consistent taste and composition.

UF-treated water can be used for:

-

Equipment cooling systems

-

Cleaning and rinsing solutions

-

Process water for formulations

Compared to traditional sand or multimedia filters, UF systems offer more stable water quality, higher automation, and are better suited for large-scale, continuous industrial operations. Additionally, UF systems serve as pre-treatment for RO systems, prolonging membrane life and reducing maintenance costs.

4. Wastewater Reuse: The Key to Closed-Loop Water Management

As environmental regulations tighten, factories must incorporate wastewater reuse into their overall water management strategies.

UF ultrafiltration systems serve as an essential pre-treatment module for reclaimed water. They can effectively remove:

-

Suspended particles

-

Residual oils

-

Colloidal pollutants

-

Microbial residues

After UF treatment, water can enter the RO system to become reusable water suitable for:

-

Facility cleaning and flushing

-

Cooling tower replenishment

-

Non-critical process water supply

WTEYA’s integrated UF + RO systems have achieved 60%-80% water reuse rates in multiple industrial projects, significantly reducing water costs and environmental discharge pressures.

5. Why UF Systems Are Suitable for “Full-Process” Water Management

UF ultrafiltration systems are highly modular and integrable. Whether handling raw water, process water, or reclaimed water, UF equipment can be flexibly implemented for unified operation and centralized management.

Key advantages include:

-

Standardized design – allows rapid deployment

-

Supports automated cleaning and remote monitoring

-

Adaptable to various water qualities – strong operational stability

-

Easy maintenance – reduces long-term operational costs

WTEYA provides one-stop support from design, selection, installation, to after-sales service, including OEM/ODM customization, helping global clients rapidly build ultrafiltration solutions tailored to their needs.

Conclusion: From Water Treatment Units to Smart Factory Water Management

Traditionally, water treatment was viewed as a passive cost center. Today, it has become a component of corporate competitiveness. By deploying UF ultrafiltration systems, companies can not only improve water utilization efficiency but also move toward intelligent, environmentally friendly, and sustainable operations.

From raw water treatment, to production purification, to wastewater reuse, UF systems are becoming a core technology for full-process factory water management. For companies seeking stable, efficient, and scalable solutions, WTEYA’s UF ultrafiltration systems are a reliable choice.

Why Choose WTYEA?

WTYEA Is Recruiting Global Partners!

We welcome your partnership. As a brand with nearly 20 years of experience, WTEYA offers various preferential policies, professional training guidance, and comprehensive technical support you can rely on!

👉 Let WTYEA help you achieve unmatched water quality performance!