High-Salinity Wastewater Treatment in the Coal Chemical Industry: Enabling Water Reuse and Sustainable Development

High-salinity wastewater treatment has become one of the key technologies driving resource recovery and green transformation in the coal chemical industry.

As environmental regulations tighten and water scarcity intensifies, treating wastewater with high salinity, complex organics, and strong toxicity has become a pressing challenge for enterprises.

WTEYA Group provides integrated high-salinity wastewater treatment solutions that offer stable, efficient, and energy-saving pathways for water reuse in coal chemical operations.

🧪 Challenges of High-Salinity Wastewater in Coal Chemical Processes

Wastewater generated in coal chemical production is often characterized by high COD, ammonia nitrogen, and salt content.

Traditional methods, such as biological or physicochemical treatments, often fail to meet discharge or reuse standards.

Effective treatment must not only remove organic pollutants but also address salt concentration and crystallization, which present high technical barriers, significant energy consumption, and cost sensitivity.

⚙️ WTEYA’s Core Treatment Technology

WTEYA employs a multi-stage integrated process consisting of:

-

Pretreatment

-

MVR (Mechanical Vapor Recompression) evaporation

-

Salt crystallization

This approach first reduces the organic load (COD) through high-efficiency pretreatment.

Then, using MVR evaporators, it separates water from salt under low energy consumption conditions.

The recovered distilled water can be reused in industrial processes, while the concentrated brine undergoes crystallization and solidification, aiming for near-zero liquid discharge (ZLD).

♻️ Water Reuse: Energy Saving Meets Emission Reduction

With WTEYA’s high-salinity wastewater treatment system, coal chemical enterprises can reuse distilled water in applications such as cooling towers or production processes.

This reduces dependence on external water supplies and significantly cuts wastewater discharge volumes. Moreover, thanks to MVR’s reuse of secondary steam, energy consumption is far lower than traditional multi-effect evaporators, which helps optimize operational costs over the long term.

📊 Smart Control and Engineering Advantages

WTEYA systems feature automated control, real-time monitoring, and remote operation & maintenance.

Their modular design allows for flexibility in installation, easy adaptation to complex working conditions, and low maintenance costs.

These advantages make the solution ideal for:

-

Coal chemical industrial parks

-

Coking plants

-

Coal-to-oil and coal-to-olefin projects

-

Any setting with an urgent need for wastewater reuse and ZLD compliance

🔧 Why Choose WTEYA Group?

WTEYA is a trusted brand with over a decade of experience in industrial water treatment.

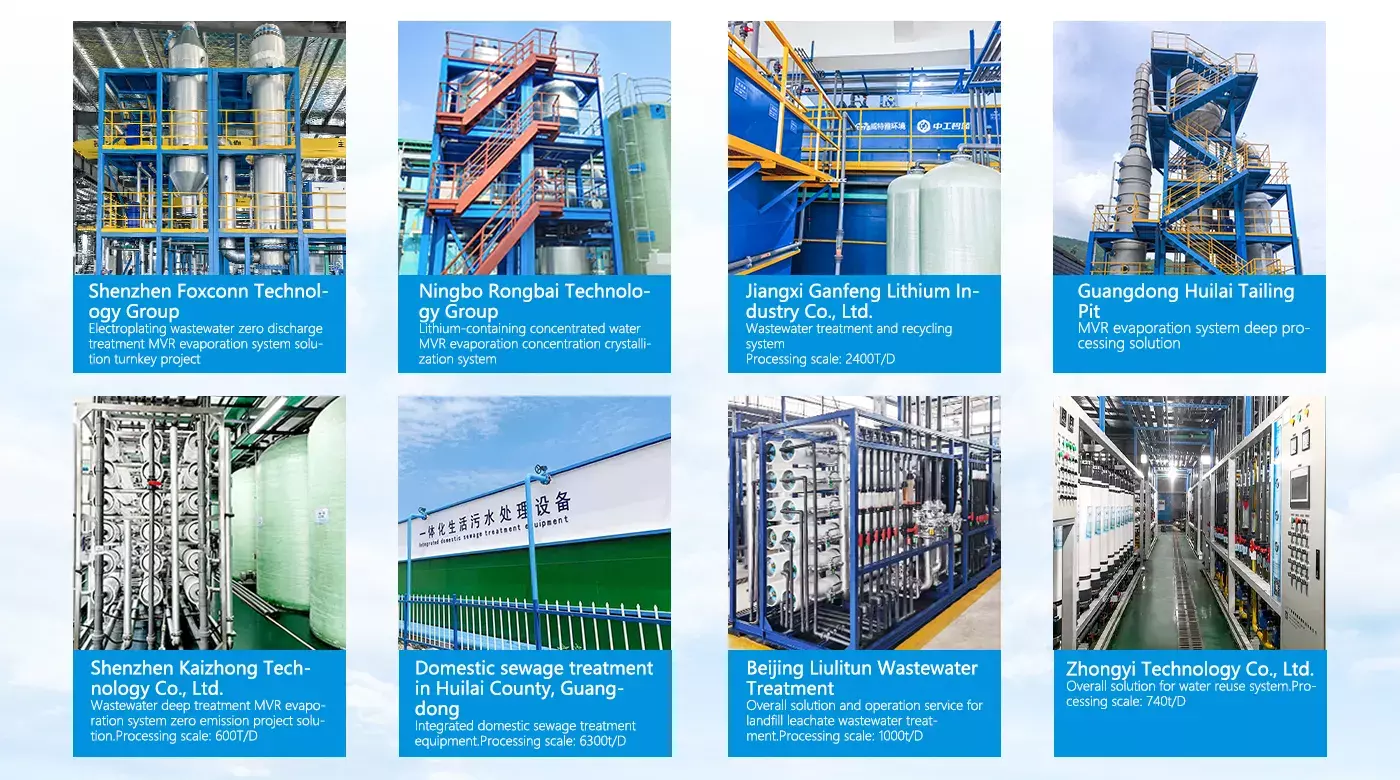

We have delivered reliable, high-performance solutions to global clients including Foxconn, Huawei, Ganfeng Lithium, and Ronbay Technology, with over 100 successful project cases and consistently positive feedback. We support both OEM & ODM customization, providing tailored solutions to meet your specific needs.

🤝 WTEYA Is Looking for Global Distributors!

Join us! As a 16-year established brand, WTEYA offers:

-

Attractive partnership incentives

-

Professional training and technical guidance

-

Comprehensive after-sales and engineering support

We’re ready to grow with you.

📧 Email: info@wteya.com

📱 WhatsApp: +86-1800 2840 855

Let WTEYA help you achieve outstanding water quality — efficiently, sustainably, and reliably.