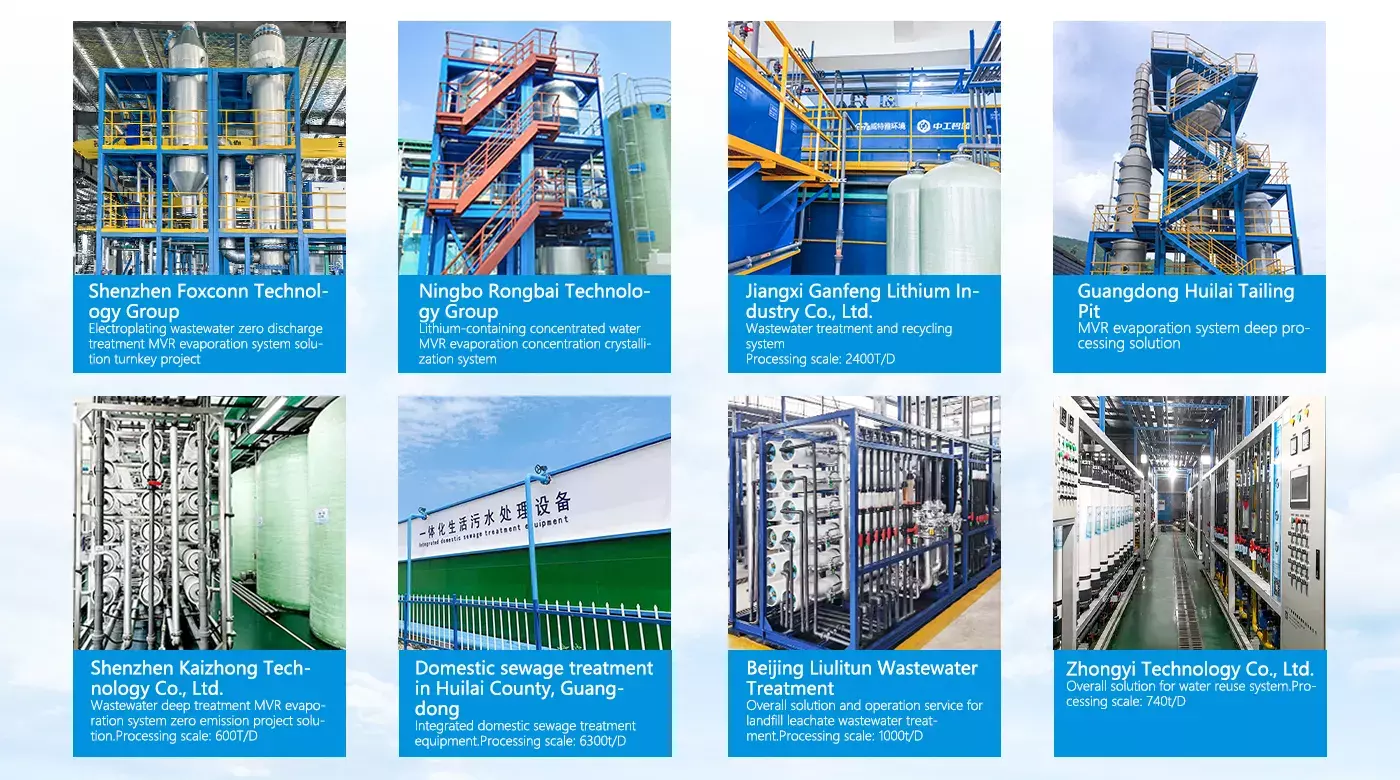

WTEYA is a brand you can trust, with over a decade of extensive experience providing efficient and reliable water treatment solutions to numerous well-known companies worldwide. We have successfully implemented projects for publicly listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with over a hundred project cases earning strong trust and praise from our clients. We support OEM & ODM customization, offering tailored solutions to meet your unique needs.

How to Choose the Right MBR Membrane Bioreactor System for Your Industrial Wastewater Treatment Needs?

19 Sep, 2025 5:36pm

With increasingly strict global environmental regulations and growing corporate focus on sustainability, more and more industrial users are seeking efficient and reliable wastewater treatment solutions. The MBR (Membrane Bioreactor) system has become a preferred technology in industrial wastewater treatment due to its outstanding performance and compact design.

However, not every MBR system can meet the specific needs of each factory. When purchasing an MBR system, companies must consider multiple factors to ensure maximum return on investment and long-term stable operation. This article will guide you through the key aspects to consider when selecting an industrial MBR system.

1. Understand Your Wastewater Quality and Treatment Goals

The first step in selecting the right system is a thorough understanding of your wastewater characteristics, including:

-

Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD) levels

-

Ammonia nitrogen, total nitrogen, heavy metal content

-

Suspended solids (TSS) concentration

-

Daily flow rates and fluctuations

-

Presence of oils, toxic substances, or other contaminants

WTEYA, as an experienced MBR industrial wastewater solution provider, can tailor solutions based on different industrial sectors (e.g., electronics, chemical, textile, food) to ensure both treatment efficiency and system stability.

2. Prioritize Compact System Design and Footprint

Unlike traditional biological treatment combined with secondary sedimentation tanks, MBR systems use membrane separation to replace settling tanks, significantly reducing overall space requirements. This is ideal for industrial facilities or urban industrial parks with limited space.

WTEYA’s MBR membrane bioreactor system features:

-

High integration and compact structure

-

Modular and containerized design for flexibility

-

Adaptability to different spatial constraints

For clients needing rapid installation or retrofitting older plants, WTEYA provides plug-and-play integrated membrane treatment units, saving civil construction costs and shortening installation timelines.

3. Membrane Quality Determines System Lifespan

The membrane is the “heart” of an MBR system, directly affecting effluent quality and maintenance costs. Key factors to consider include:

-

Membrane material: PVDF membranes are highly resistant to fouling and have longer lifespans

-

Membrane type: Hollow fiber or flat sheet membranes, each suited to different water qualities

-

Flux stability and backwash cycles: Determines cleaning frequency and energy consumption

-

Support for automatic CIP cleaning

WTEYA uses high-quality external membrane components combined with intelligent operating strategies to control membrane fouling and extend service life.

4. Intelligent Operation and Ease of Maintenance

Advanced MBR systems should not only perform well but also be easy to operate. WTEYA continuously upgrades system intelligence, offering:

-

PLC or SCADA automated control

-

Simple operation even for personnel with limited experience

5. Customization and OEM/ODM Support

Every project has unique operating conditions, budgets, and spatial constraints—standard equipment cannot fit all needs. WTEYA offers:

-

Customized membrane quantities and treatment scales

-

OEM services for labeling and integration

-

ODM deep customization to meet differentiated process requirements

-

Modular design for easy expansion or relocation

We welcome collaboration with global industrial agents, engineering companies, and environmental integrators to deliver flexible, cost-effective wastewater solutions.

6. Lifecycle Costs and After-Sales Support

Many clients overlook that the true value of an MBR system is determined not by initial purchase price but by total cost of ownership (TCO). Key factors include:

-

Membrane replacement cycle and consumables cost

-

Energy consumption and aeration efficiency

-

Failure rate and maintenance labor

-

Ease of upgrades or part replacements

WTEYA provides comprehensive after-sales support, including remote technical assistance, maintenance reminders, rapid spare parts supply, and operator training to ensure long-term system stability.

7. Application Cases and Industry Experience

WTEYA’s MBR industrial wastewater systems have been widely applied in:

-

High-organic wastewater from textile and leather factories

-

Heavy metal wastewater from semiconductors and printed circuit boards

-

Medium-to-high COD wastewater from food processing plants

-

Wastewater with high variability from pharmaceutical or fine chemical factories

-

Centralized wastewater treatment stations in industrial parks

Whether you are a small processing facility or a large industrial group, we can match the right system for your needs.

Conclusion: Simplify Wastewater Treatment with a Professional MBR System

MBR technology has become mainstream in industrial wastewater treatment due to its high efficiency, stable operation, and multiple advantages such as energy savings, compact footprint, and excellent effluent quality. Choosing WTEYA ensures:

-

Efficient solid-liquid separation and organic pollutant removal

-

Intelligent control and easy maintenance

-

Space-friendly, compact structure suitable for retrofits or new builds

-

Flexible OEM/ODM cooperation

-

One-stop service and global technical support

Whether you are a project contractor, equipment agent, environmental integrator, or end-user, WTEYA is your trusted MBR system partner.

Why Choose WTYEA?

WTYEA Is Recruiting Global Partners!

We welcome your partnership. As a brand with nearly 20 years of experience, WTEYA offers various preferential policies, professional training guidance, and comprehensive technical support you can rely on!

👉 Let WTYEA help you achieve unmatched water quality performance!