Smart Environmental Protection: How Can Leachate Treatment Achieve “Unmanned Operation”?

With China’s “dual carbon” strategy steadily advancing and environmental policies becoming increasingly stringent, landfill environmental management has become a top regulatory focus. Among all challenges, landfill leachate treatment—characterized by high pollutant intensity and unstable water quality—is regarded as the “lifeline of a landfill.”

Traditional treatment methods rely heavily on manual operation and maintenance, leading to slow fault response, delayed data monitoring, and a high risk of excessive discharge or resource waste.

Today, with the continuous evolution of smart environmental technologies, “unmanned operation” leachate treatment systems are emerging as a key industry trend.

Why Is “Unmanned Operation” an Inevitable Trend?

1. Complex Leachate Treatment vs. Limited On-site Resources

Landfill leachate contains high concentrations of organic matter, ammonia nitrogen, heavy metals, and persistent pollutants. Traditional stations require frequent monitoring and parameter adjustments. Yet most landfills are located in remote areas with insufficient professional operators, often resulting in poor oversight or minimal maintenance.

2. Stricter Environmental Supervision → Real-time Monitoring Becomes Essential

The Ministry of Ecology and Environment and local bureaus are tightening online monitoring requirements. Non-compliant discharge now risks heavy fines or forced shutdowns, pushing treatment systems toward digitalization, visualization, and automation.

3. Balancing Cost Control and Long-term Operation Efficiency

Leachate treatment projects often last over 20 years. Reducing long-term labor costs and minimizing operational risks has become a decisive factor for project success.

WTYEA: Building an “Unmanned” Leachate Treatment System

As a provider of environmental protection equipment and solutions, WTYEA enables true unmanned operation through automation, intelligence, and modular integration—delivering one-click start, remote monitoring, self-diagnosis, and predictive maintenance.

✅ 1. Fully Automated Process Control

-

PLC + HMI-based control architecture

-

Integrated pre-treatment, membrane filtration, RO concentration, and advanced treatment modules

-

Automatic dosing, liquid level regulation, flow adjustment, and online cleaning

👉 Example: If influent COD or ammonia nitrogen rises unexpectedly, the system automatically activates enhanced pre-treatment, preventing damage to the RO system.

✅ 2. Cloud-based Remote Monitoring & Big Data Analytics

All equipment connects to WTYEA’s smart water management cloud platform, giving operators real-time access via web or mobile app to:

-

Operating status and alarm history

-

Key parameter trends: pH, COD, ammonia nitrogen, pressure, membrane flux

-

Chemical consumption and spare part alerts

-

Auto-generated daily operation reports

-

Remote fault diagnosis and support

📡 Supports integration with government regulatory platforms and third-party labs, ensuring full compliance and data traceability.

✅ 3. AI-driven Predictive Maintenance

With accumulated operational data and modeling, the system enables:

-

Membrane fouling prediction → proactive cleaning

-

Reaction tank retention time prediction → dosing optimization

-

Consumable lifespan prediction → automated replacement reminders

This shifts maintenance from “fix after failure” to “prevent before breakdown.”

✅ 4. Modular & Flexible Deployment

WTYEA offers containerized or skid-mounted systems, adaptable to different landfill or emergency scenarios:

-

IP65-rated for outdoor deployment

-

Parallel expansion to meet fluctuating inflow volumes

-

Solar + battery storage options for remote power supply

Case Study: From “Operation Anxiety” to “Smart Stewardship”

At a remote landfill in Yunnan, staff shortages left the traditional treatment station running intermittently, resulting in multiple violations by the local environmental bureau.

After deploying WTYEA’s smart leachate system:

-

Daily operational data is uploaded automatically

-

The local bureau monitors compliance online in real time

-

Remote experts diagnose issues and issue adjustment commands

Within two months, continuous compliance was achieved, and the landfill manager remarked: “For the first time, we can finally sleep peacefully.”

“Unmanned” ≠ “Unsupervised” — The Future of Smart Environmental Protection

Unmanned operation does not mean zero human involvement. Instead, it shifts manpower from repetitive manual tasks to system optimization and predictive management.

Future landfill leachate treatment will evolve toward:

-

More precise sensing and control

-

Stronger edge-AI algorithms for water quality adjustment

-

ESG integration of carbon emissions and energy consumption data

-

Government-enterprise data sharing and regional water network integration

WTYEA is leading this shift—transforming landfill leachate treatment from reactive emergency response to proactive intelligent management, from people watching machines to machines managing for people.

Unmanned operation is more than just a technological upgrade—it represents a deeper shift in environmental governance philosophy.

If you are seeking solutions in leachate treatment, system integration, or intelligent O&M, WTYEA provides one-stop customized solutions to help you cut costs, achieve compliance, and enhance operational efficiency.

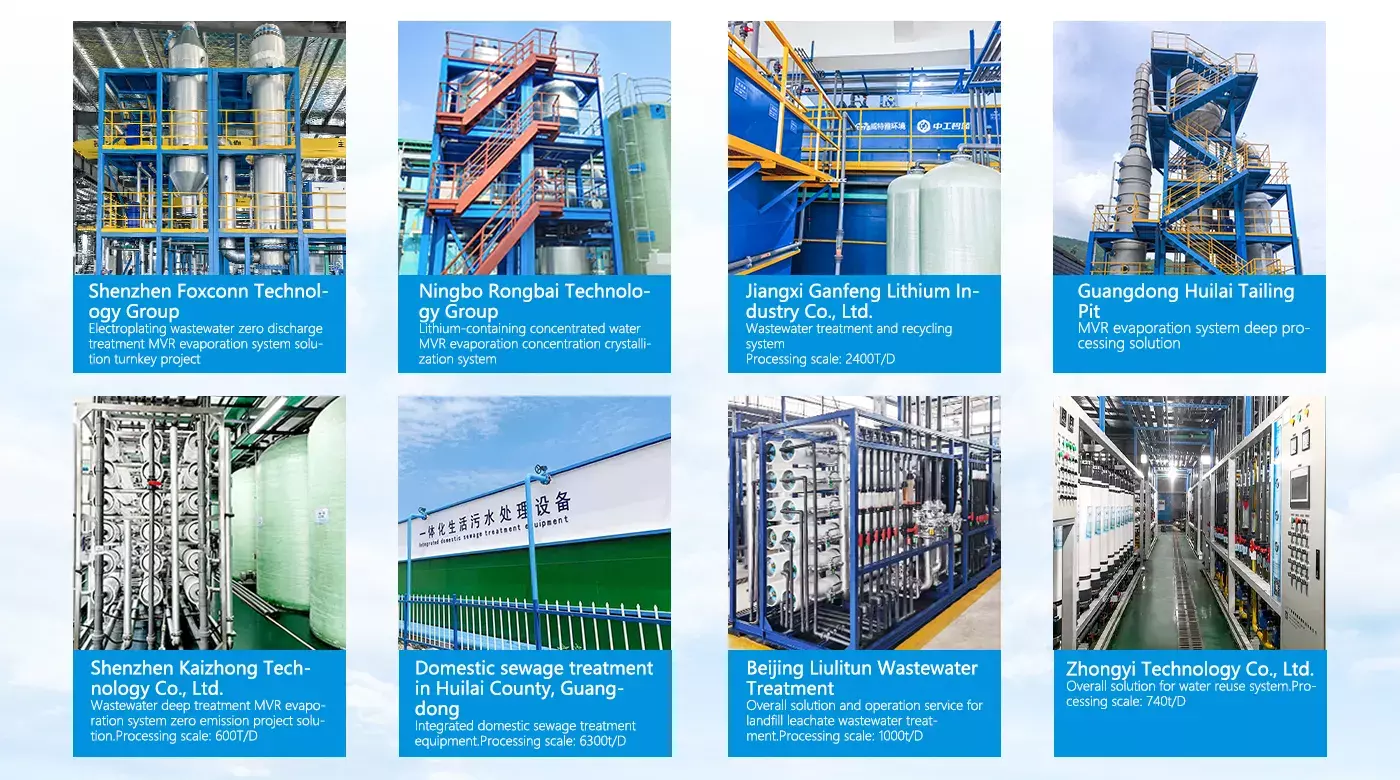

Why Choose WTYEA?

-

Over 16 years of expertise in water treatment solutions

-

Trusted by global leaders including Foxconn, Huawei, Ganfeng, and Ronbay

-

100+ successful projects with excellent client feedback

-

OEM & ODM support for tailored solutions to meet your unique needs

WTYEA Is Recruiting Global Partners!

Join us as a distributor and benefit from:

-

Attractive incentive policies

-

Professional training & guidance

-

Comprehensive technical support

📩 Email: info@wteya.com

📱 WhatsApp: +86-1800 2840 855

👉 Let WTYEA help you achieve unmatched water quality performance!