Reverse Osmosis Water Plant

Menu

Latest News

Reverse Osmosis Water Plant

Clean Water For All

From small private businesses to large corporations, everyone needs pure water of the highest quality. The working principle of a (RO) reverse osmosis plant is based on the principle of the natural process of osmosis. Reverse osmosis water treatment systems are used to solve a wide range of problems in any type of industry (pharmaceuticals, microelectronics, chemicals and food production, etc.).

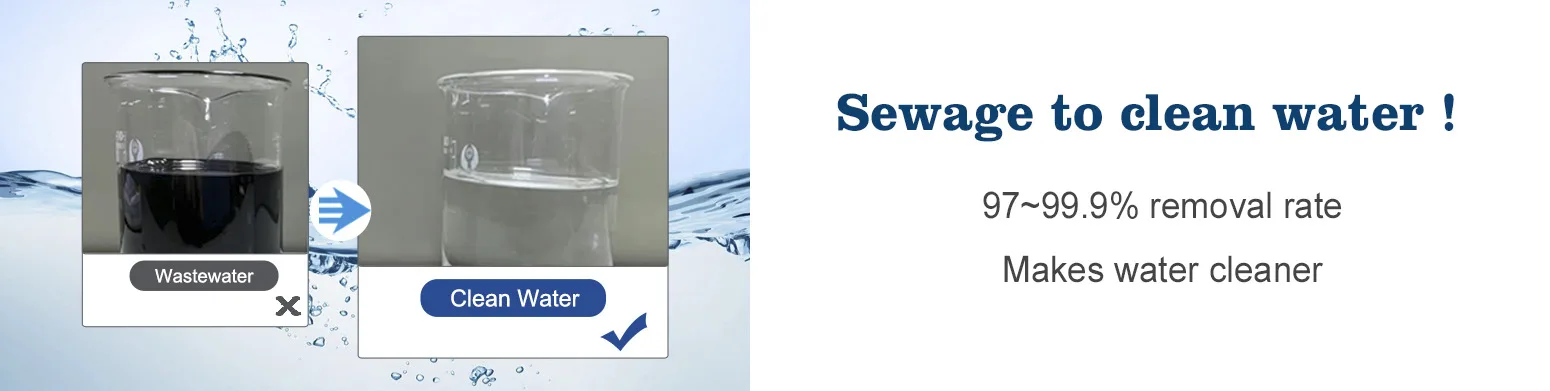

The main advantages of reverse osmosis water treatment plants are high efficiency and high water purification rates, which can remove up to 97-99.9% of all pollutants. The main impurities removed by industrial osmosis are: heavy metal ions, sodium, potassium, sulfate, chloride, boron, fluoride and other inorganic ions.

Are you still worried about these?

Like the high concentration of pollutants in sewage, the purity of pure water is not enough, and the water treatment is not clean.

WTEYA Reverse Osmosis System

What can it bring?

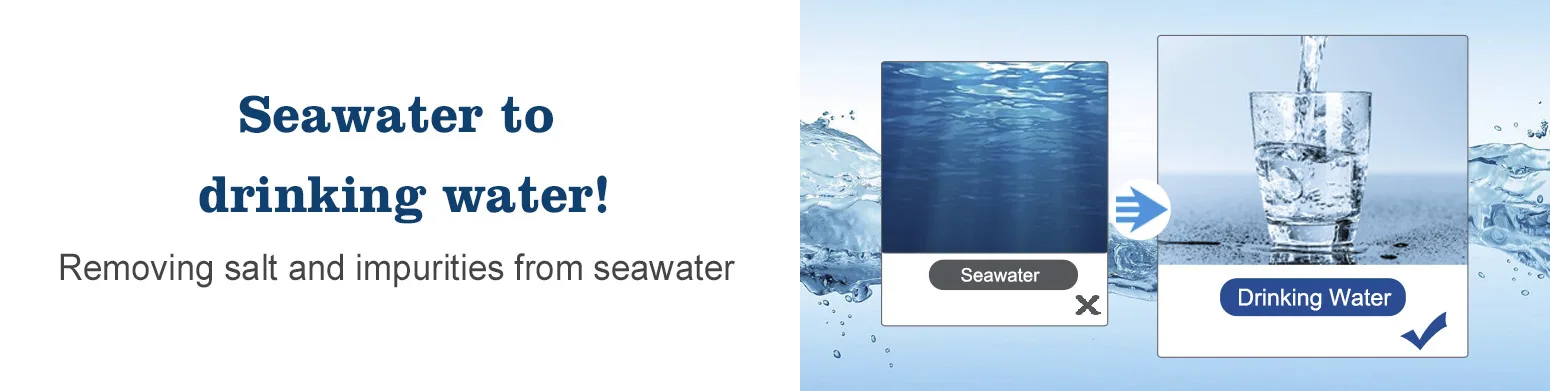

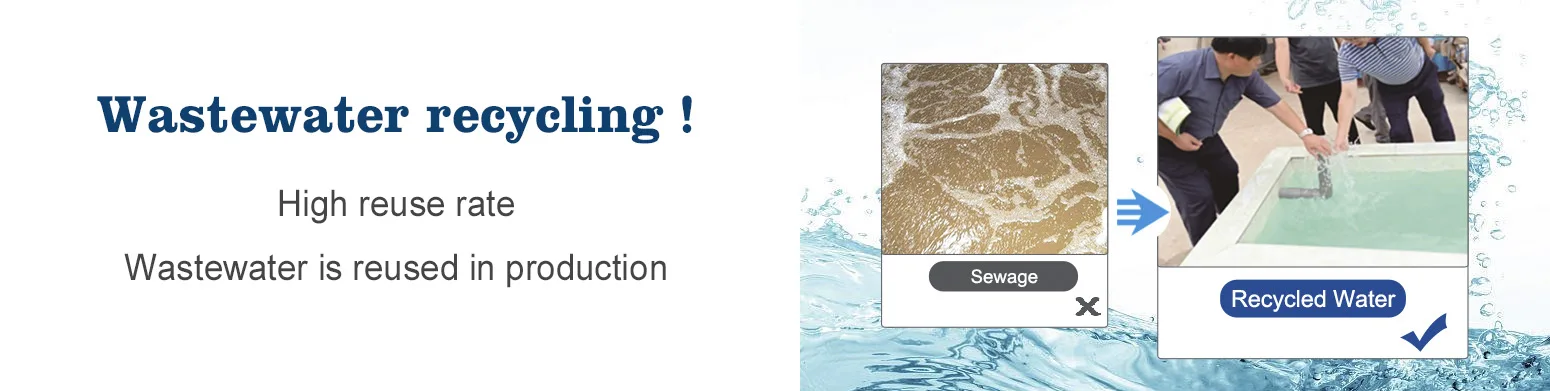

Our reverse osmosis water treatment plants are a great choice when you want to treat large volumes of water quickly. Turn dirty water into clean water, and salt water into fresh or drinking water. It's easy!

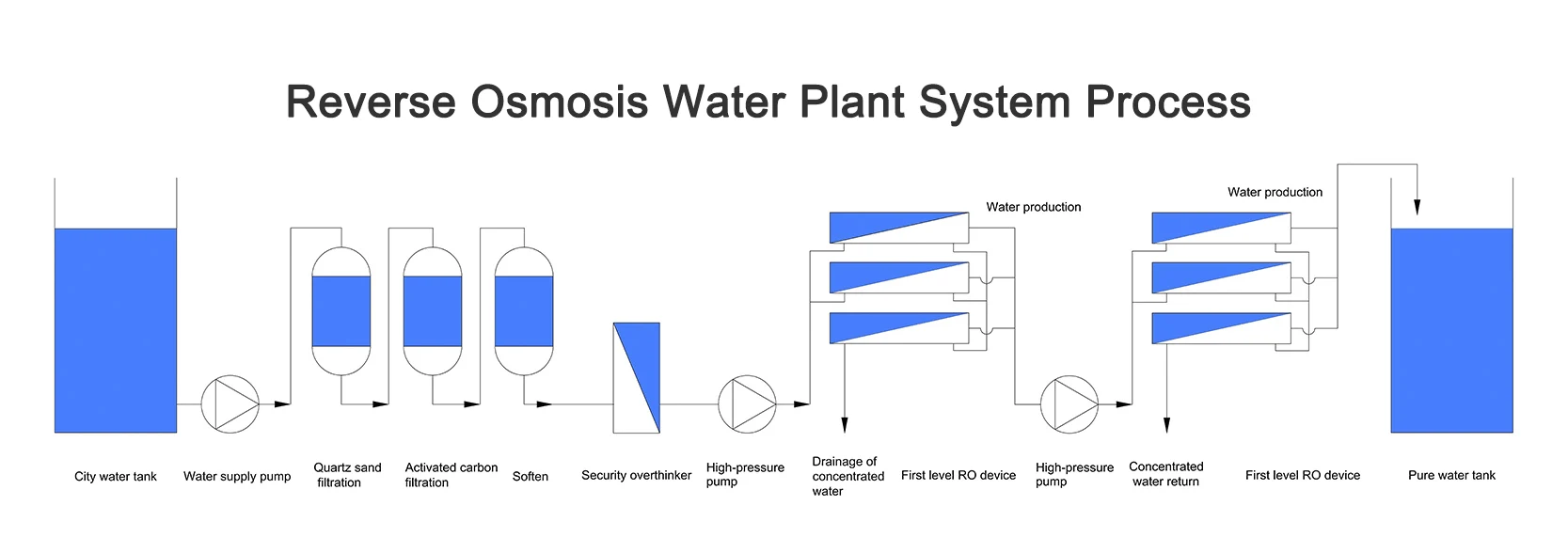

How it works

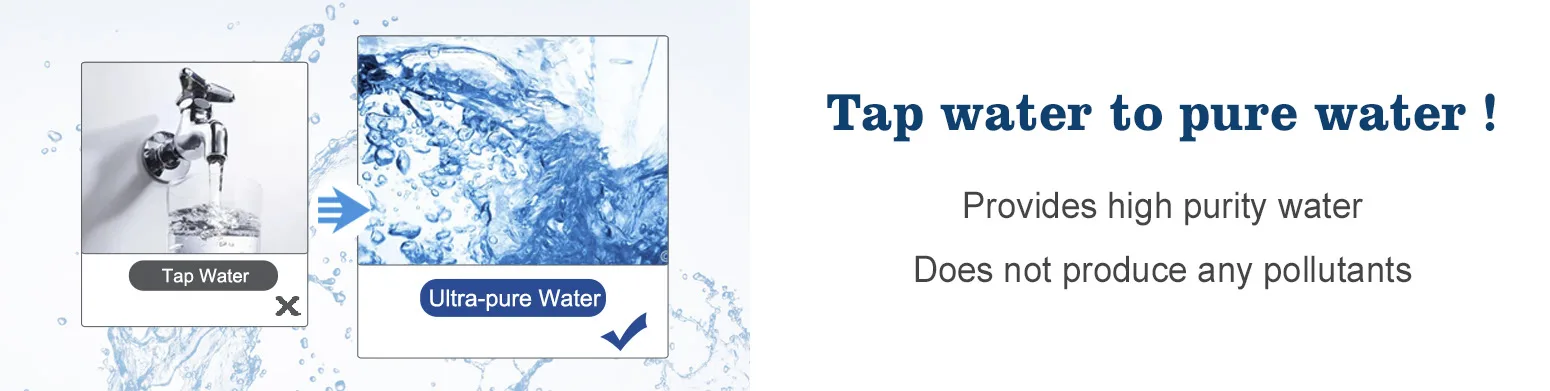

RO reverse osmosis technology is a membrane separation and filtration technology that uses pressure difference as a driving force. Its pore size is as small as nanometer level. Under a certain pressure, H2O molecules can pass through the RO membrane, while inorganic salts, heavy metal ions, organic matter, colloids, bacteria, viruses and other impurities in the raw water cannot pass through the RO membrane. Thus, the pure water that can pass through and the concentrated water that cannot pass through are strictly distinguished.

97~99% Removal Rate

WTEYA (RO) reverse osmosis water treatment plant uses multi-stage physical fine filtration + reverse osmosis technology filtration to effectively filter out scale, heavy metals, colloids, viruses and bacteria, etc. It can easily convert sewage into clean water, seawater into drinking water or purified water, and solve any water treatment pollutants.

- Removal rate > 99%

- Chloride ion 99.30%

- Sodium ion 99.39%

- TDS 99.42%

- Conductivity 99.22%

What are its features?

Introducing reverse osmosis water treatment equipment into production helps improve production efficiency and quality: reduce water hardness and remove various pollutants. We can customize various models of water treatment equipment, allowing you to obtain high-quality water at a low cost.

Where it can be used

WTEYA's reverse osmosis water treatment plant is a highly efficient multi-stage RO membrane filtration technology equipment. It can work 24 hours a day without interruption, stable operation, and guarantee your water needs! It has an integrated design, portable and modular, and more convenient!

Parameter selection

|

Model |

Water volume |

Power |

Water quality |

Dimensions(mm) |

Material |

|

WTY-RO2-1 |

1m³/h |

5.5kw |

<5 μS/cm |

2000 × 1000 × 2000mm(H) |

304/ UPVC/ Polyamide/ |

|

WTY-RO2-2 |

2m³/h |

6.3kw |

<5 μS/cm |

2000 × 1000 × 2000mm(H) |

|

|

WTY-RO2-5 |

5m³/h |

13.2kw |

<5 μS/cm |

4500 × 2400 × 2400mm(H) |

|

|

WTY-RO2-10 |

10m³/h |

33.0kw |

<5 μS/cm |

5000 × 2600 × 2500mm(H) |

|

|

WTY-RO2-20 |

20m³/h |

67.0kw |

<5 μS/cm |

6000 × 1800 × 2800mm(H) |

|

|

8000 × 2600 × 3000mm(H) |

What does it consist of

You have different Reverse Osmosis (RO) options, depending on your water needs, available space, and budget. All RO options are compatible with AC PSUs and are available in portable and modular configurations.

Frequently Asked Questions

| Questions |

Countermeasures |

|

Does the reverse osmosis system consume a lot of energy?

|

The WTEYA reverse osmosis water treatment plant uses advanced RO technology, with ultra-high water production rate, large flow rate and low energy consumption. |

|

Is the reverse osmosis system prone to failure?

|

The WTEYA reverse osmosis plant uses durable materials, is corrosion-resistant and has a long service life. |

|

Does the treated water meet the standards?

|

The water treated by the WTEYA reverse osmosis plant is clean and clear, with high purity and meets the discharge standards. |

|

Is the maintenance cost of the reverse osmosis system high?

|

The WTEYA reverse osmosis plant adopts a portable modular design. Installation and maintenance are very simple and low cost. |

|

Operator error may cause system failure?

|

The WTEYA reverse osmosis plant uses an automated control system. One-button start and stop greatly reduce the occurrence of failures and accidents. |

|

Why is the reverse osmosis system important?

|

The WTEYA reverse osmosis plant has a wide range of uses. It can convert seawater into drinking and domestic water in seconds. For islands and coastal cities with scarce water sources, it can ensure a stable supply of fresh water. It can also convert sewage into clean water to achieve resource recycling. |

|

Who owns the plant?

|

The reverse osmosis plant is developed and produced by WTEYA manufacturers. We provide OEM and ODM services, free design, and recruit agents worldwide. |

|

What is the impact on the environment?

|

The WTEYA reverse osmosis plant places a high priority on minimizing its impact on the terrestrial and aquatic environments. To support this goal, a strict environmental monitoring program is implemented. The plant has minimal impact on the environment. |

We did it!

WTEYA is a manufacturer with over 15 years of experience.

We provide customized support, including OEM ODM services.

Reverse Osmosis (RO) Plant costing

How much does a reverse osmosis plant cost? We are ready to provide you with detailed information about the different models, their technical characteristics, performance. We offer a full range of OME&ODM services, from advice and assistance in selecting equipment to equipment supply, installation and configuration. Our goal is to provide you with the necessary equipment to effectively solve the desalination problems in your specific case.

So, you need to email us at info@wteya.com

Our manager will prepare an excellent quote for you

Previous: RO Water Treatment Systems

Next: No More