WTEYA Group MVR Evaporation System: Advanced Applications for Fracturing Flowback and Coal Chemical Wastewater

The MVR (Mechanical Vapor Recompression) evaporation system from WTEYA Group plays a transformative role in addressing two highly challenging industrial wastewater problems: fracturing flowback fluid in oil and gas extraction and complex wastewater from coal chemical production. These wastewater types are not only high in salinity and complex in organic content, but also difficult to treat using traditional methods. The MVR technology offers a cleaner and more efficient solution.

⚙️ Working Principle of the MVR Evaporation System

The MVR evaporation system from WTEYA Group recycles the thermal energy within the system using a mechanical vapor recompression (MVR) recovery mechanism, significantly reducing energy consumption. The system compresses and reuses the steam generated during the evaporation process, minimizing steam demand while achieving efficient separation.

🛢️ Application in Fracturing Flowback Fluid Treatment

Fracturing flowback fluid contains sand, oil, heavy metals, and various chemical additives. WTEYA's MVR evaporation system efficiently concentrates these complex wastewater types, separating reusable water, concentrated brine, and solid waste. The treated distilled water can be reused for drilling operations, while the concentrated brine is easy to dispose of or can be crystallized for recovery.

🏭 Application in Coal Chemical Wastewater Treatment

Coal chemical wastewater often contains ammonia nitrogen, phenols, cyanides, and other hard-to-degrade pollutants. WTEYA Group's MVR evaporation system effectively concentrates the wastewater, reducing the pollutant load and making subsequent processes such as incineration, crystallization, or advanced oxidation treatment more economical and efficient.

🔋 Energy-saving and Environmental Benefits

Compared to traditional multi-effect evaporation systems, WTEYA's MVR system is designed with a focus on low energy consumption and reducing CO2 emissions. The system operates in a closed loop, minimizing water loss and increasing resource recovery rates. It supports the Zero Liquid Discharge (ZLD) strategy, meeting modern environmental standards.

🔧 Why Choose WTEYA Group?

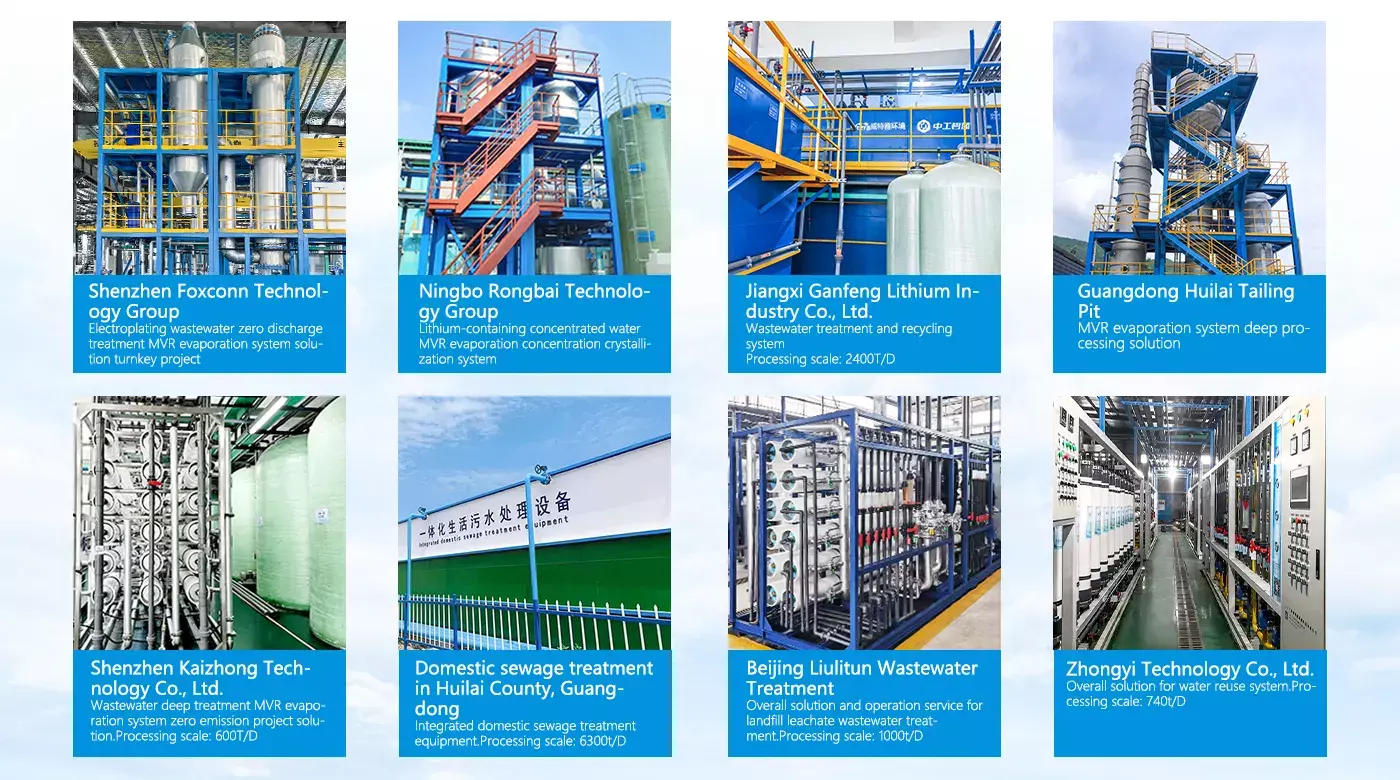

WTEYA is a trusted brand with over a decade of experience, providing efficient and reliable water treatment solutions to many well-known global companies. We have successfully implemented projects for listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with more than a hundred project cases, gaining the trust and praise of our clients. We support OEM&ODM customization and provide tailored solutions to meet your unique needs.

🔧 WTEYA is Recruiting Agents!

We welcome your partnership! As a well-established 16-year-old brand, WTEYA offers a range of promotional policies, professional training, and comprehensive technical support. Trust in us for a prosperous future!

*Email: info@wteya.com

*WhatsApp:+86-18002840855

Let us help you achieve unparalleled water quality!