Efficient mine water zero liquid discharge solution - WTEYA can help you easily solve it!

Mine water refers to wastewater that enters the mining space during coal mining and must be discharged in time to ensure safe production. Although its pollution level is usually light, the discharge volume is large. After proper treatment, mine water can become a valuable recycled water resource. However, with the continued progress of coal mining, the groundwater level in the mining area has dropped significantly, and groundwater resources are becoming increasingly scarce, making the conservation and reuse of water resources particularly important.

Mine water is essentially groundwater, but its water quality characteristics are significantly different from ordinary groundwater. Due to long-term storage underground, mine water dissolves a large amount of minerals. At the same time, underground mining operations will also mix pollutants such as oil and organic matter into the water body, making its water quality composition more complex.

WTEYA provides a mine water zero liquid discharge (ZLD) system that can deeply purify and resource-process mine water. The system not only effectively reduces the pollution of mine water to surface water bodies, but also converts it into a green, renewable water source, alleviating the water use contradiction in the mining area from the source.

✅ Mine water quality characteristics

Mine water has the following typical characteristics, which make its treatment and reuse process more complicated:

High suspended matter content: When passing through the working face, mine water will carry a large amount of suspended matter such as coal powder and rock particles, resulting in turbid water quality and poor sensory properties.

High mineralization: The salt content in mine water is usually 1000~3000mg/L, mainly containing calcium, magnesium, sodium, potassium, sulfate, bicarbonate, and other ions.

Strong acidity: The pH value of mine water is usually between 3.0 and 5.5, mainly due to the oxidation, decomposition, and dissolution of sulfides in coal and surrounding rocks.

Strong suddenness: If the old kiln water suddenly gushes out, it will cause a sharp increase in water inflow in a short period, seriously threatening the safety of the mine.

Contains special pollutants: Mine water may contain heavy metal ions, coal dust, rock dust, and even radioactive substances, posing a threat to the environment and human health.

Because of these characteristics, the treatment and reuse of mine water requires the use of special technologies and processes to deal with it.

✅ WTEYA Mine Water Zero Discharge Solution

WTEYA's ZLD system adopts a multi-stage integrated process, combining the dual goals of high efficiency and environmental protection, to provide customers with advanced deep treatment and resource recovery solutions for mine water.

1. Pretreatment stage

The V-type sand filtration system is used to remove suspended matter, colloids, iron, and manganese in the water, and other factors that affect the stable operation of the subsequent membrane system. The system has the advantages of low filter material cost, wide source, low operating cost, and easy maintenance.

2. Deep treatment stage

The mine water is deeply purified through membrane separation technology, effectively removing fluoride, total dissolved solids (TDS), sulfate, iron and manganese, chloride, and other indicators, improving the water quality of the effluent, and meeting the requirements of subsequent reuse.

3. Evaporation and crystallization stage

According to the material characteristics, the sodium sulfate system adopts the MVR falling film evaporation and concentration process. After the material is close to the saturated concentration of sodium sulfate, it enters the forced circulation crystallizer to generate sodium sulfate crystals. The heat source of the crystallizer is provided by the MVR steam compressor. After the sodium sulfate mother liquor is precipitated with mirabilite through the freezing crystallization system, the remaining supernatant enters the mixed salt system for evaporation and crystallization. After being separated and dissolved, the mirabilite returns to the sodium sulfate crystallizer for crystallization. The mother liquor of the mixed salt system finally enters the dryer for drying, achieving zero liquid discharge.

✅ Why choose WTEYA?

As a leading supplier in the field of evaporation, crystallization, and membrane treatment equipment, WTEYA is committed to providing customers with efficient and environmentally friendly overall solutions for zero discharge of mine water. We integrate advanced membrane separation technology and evaporation crystallization technology to provide full-process system design and services for mining areas, achieving the goal of reducing pollution from the source and efficiently recovering water resources.

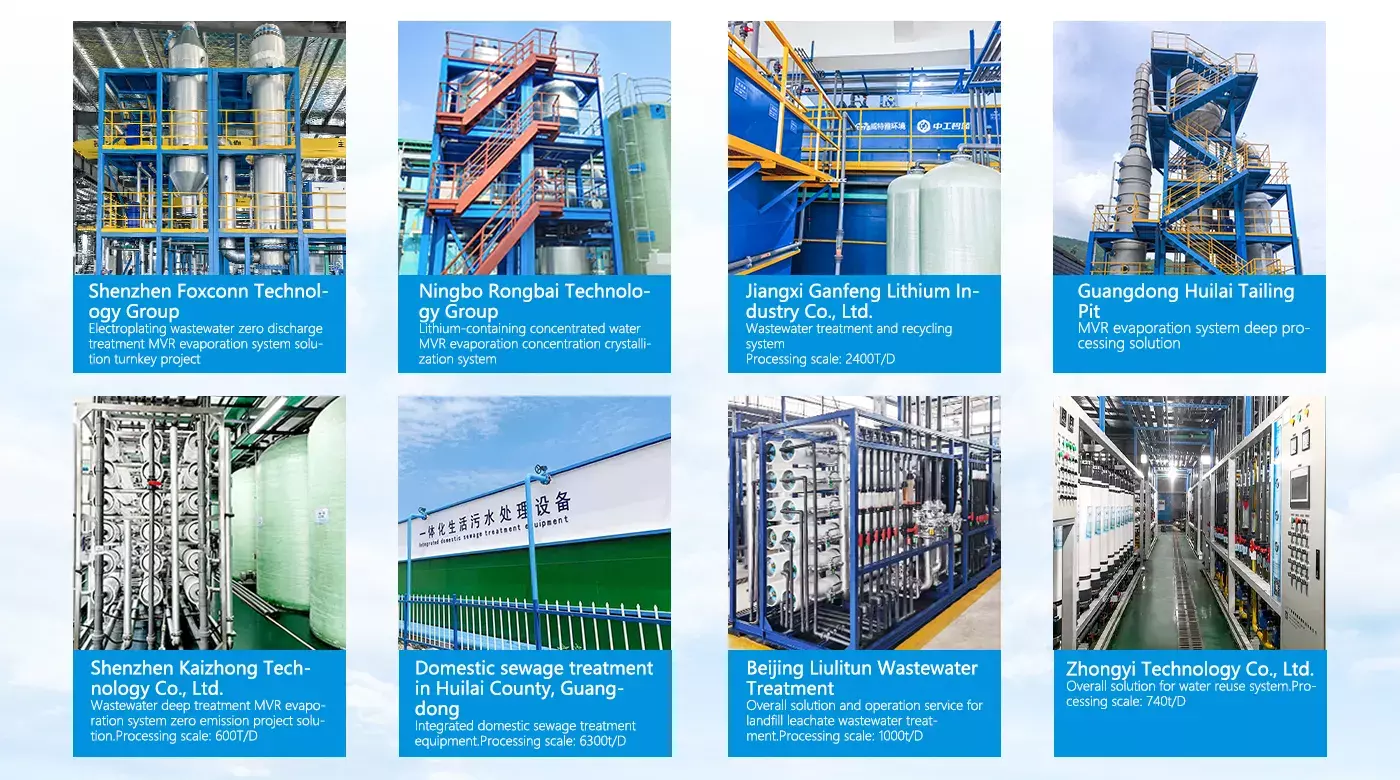

WTEYA is a brand you can trust. With more than ten years of rich experience, it has provided efficient and reliable water treatment solutions to many well-known companies around the world, and successfully implemented projects for listed companies such as Foxconn, Huawei, Ganfeng, Rongbai, etc., with more than 100 project cases, and has won the trust and praise of customers. Support OEM and ODM customization, and customized solutions to meet your unique needs.

✅ WTEYA is recruiting agents!

Welcome to join us. As a 16-year-old brand, WTEYA provides you with a variety of preferential policies, professional training guidance, and all-around technical support. It is worthy of your trust!

*Email: info@wteya.com

*WhatsApp: +86-18002840855

Let us help you achieve unparalleled water quality!