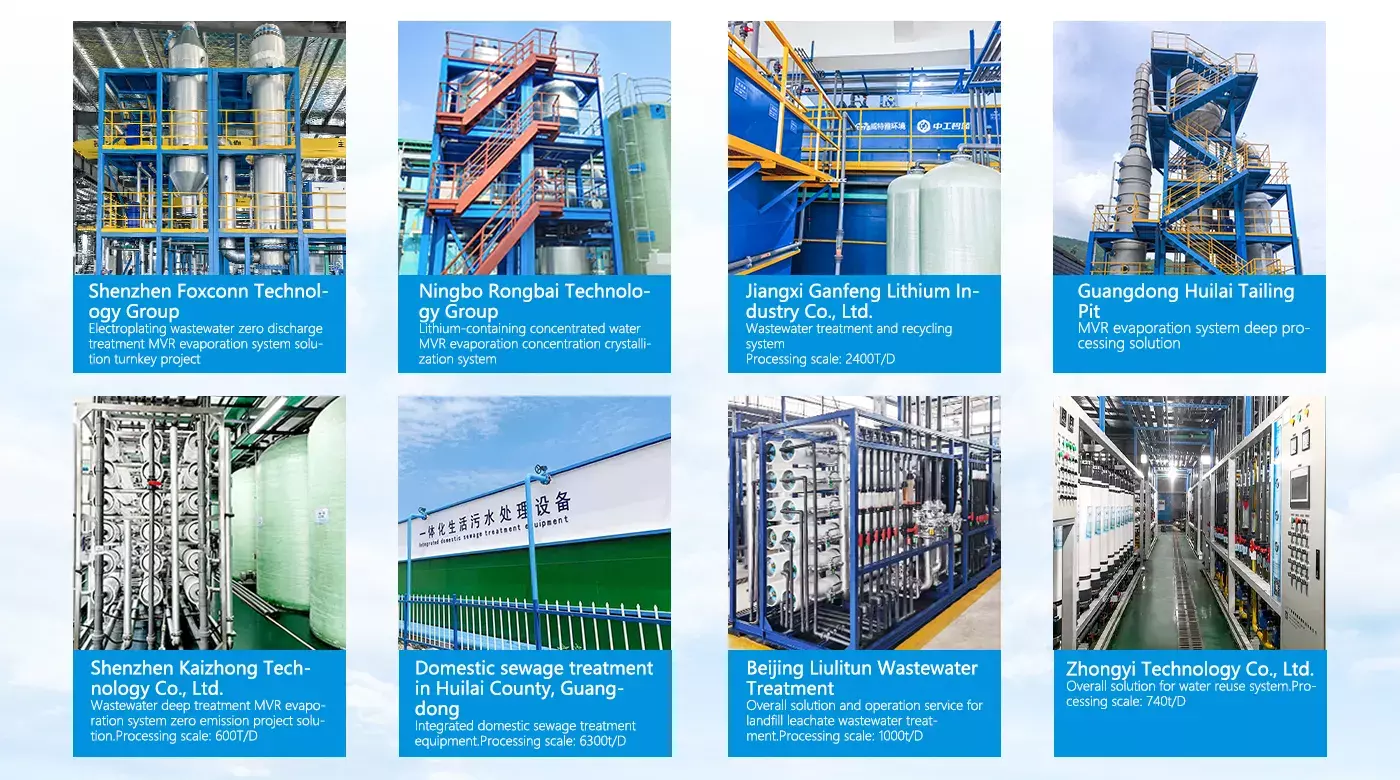

WTEYA is a brand you can trust, with over a decade of extensive experience providing efficient and reliable water treatment solutions to numerous well-known companies worldwide. We have successfully implemented projects for publicly listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with over a hundred project cases earning strong trust and praise from our clients. We support OEM & ODM customization, offering tailored solutions to meet your unique needs.

How Triple-Effect Evaporators Enhance Pharmaceutical Manufacturing Efficiency?

11 Nov, 2025 4:29pm

Maintaining high production efficiency while ensuring stringent product quality standards has always been a challenge in pharmaceutical manufacturing. Liquid concentration and solvent recovery are critical processes in this industry. Triple-effect evaporators provide a revolutionary solution. As high-efficiency, energy-saving equipment, these evaporators have become indispensable in the pharmaceutical sector. By utilizing multi-stage evaporation and heat recovery, they optimize production processes, reduce costs, and promote sustainable manufacturing practices.

This article explores how triple-effect evaporators improve efficiency in pharmaceutical manufacturing and highlights their key benefits.

What is a Triple-Effect Evaporator?

A triple-effect evaporator is an advanced evaporation system that uses multiple evaporation stages (or “effects”) to concentrate liquids efficiently. In this system:

The first evaporator generates steam to heat the second evaporator.

The second evaporator produces steam to heat the third evaporator.

This cascading process maximizes the utilization of thermal energy, significantly reducing external energy requirements.

Compared to single-effect evaporators, triple-effect systems are much more energy-efficient due to their energy recovery principle, making them ideal for precise liquid concentration and solvent recovery in pharmaceutical manufacturing.

How Triple-Effect Evaporators Boost Pharmaceutical Efficiency

1. Improved Energy Efficiency and Cost Savings 💡

Energy consumption is one of the highest operational costs in pharmaceutical production. Traditional evaporation methods often require large amounts of steam or electricity, increasing operational expenses. Triple-effect evaporators reuse steam from previous stages to heat subsequent stages, significantly reducing energy consumption.

By integrating heat pump evaporators with triple-effect systems, pharmaceutical companies can further maximize energy savings, as heat pumps recover energy from the cooling process and redirect it into the system.

2. Enhanced Product Quality and Consistency 🌟

Pharmaceutical production demands strict control over active ingredients, solvents, and other components. Triple-effect evaporators provide precise concentration, ensuring products maintain consistent quality throughout production. Operating in a controlled environment with minimal temperature fluctuations prevents the degradation of sensitive compounds. This consistency is essential for liquid formulations, syrups, and concentrated extracts, preserving the efficacy and reliability of the final product.

3. Reduced Emissions and Environmental Impact 🌍

Pharmaceutical companies face increasing pressure to reduce environmental impact. Efficient wastewater treatment and solvent recovery are critical, especially in high-volume liquid drug production.Triple-effect evaporators minimize energy usage and recover heat efficiently, reducing emissions and waste.

WTEYA’s expertise in Zero Liquid Discharge (ZLD) projects, particularly in wastewater treatment and liquid concentration, helps pharmaceutical plants adopt environmentally friendly processes. ZLD ensures all wastewater is treated, reused, or evaporated, leaving no harmful discharge.

4. Enhanced Process Control and Automation ⚙️

Automation is key in large-scale pharmaceutical production to improve operational efficiency and reduce human error. Triple-effect evaporators are equipped with advanced control systems, allowing operators to monitor and adjust parameters such as temperature, pressure, and flow rate. Automated control ensures the evaporation process remains consistent and optimal, reducing manual intervention while providing real-time data essential for quality control and continuous process improvement.

5. Flexibility for Various Liquid Products 🧪

Pharmaceutical manufacturing often involves diverse liquid products, each with unique properties. Triple-effect evaporators can easily adapt to a variety of applications:

● Concentrating herbal extracts

● Recovering solvents

● Processing pharmaceutical intermediates

As a leading industrial evaporator supplier, WTEYA offers standardized and customized solutions to meet the specific needs of the pharmaceutical sector. Whether OEM or ODM, WTEYA designs systems that fully align with client production requirements.

How WTEYA’s Triple-Effect Evaporators Enhance Pharmaceutical Operations

With extensive experience in vacuum evaporation and crystallization equipment design, WTEYA focuses on providing efficient liquid concentration and wastewater treatment solutions for pharmaceutical and chemical industries.

WTEYA has successfully implemented multiple ZLD projects, especially in wastewater treatment and liquid concentration, offering a complete one-stop service — from equipment design and installation to commissioning and technical support.

Key advantages of WTEYA triple-effect evaporators include:

● Custom solutions for optimizing liquid concentration and solvent recovery processes.

● Energy-efficient design, significantly reducing operating costs.

● Advanced control systems for improved process monitoring and automation.

● Comprehensive after-sales support, ensuring long-term, high-efficiency operation.

With proven solutions, WTEYA has become a trusted partner for global pharmaceutical manufacturers, providing high-performance evaporators that support quality control and cost efficiency.

The Future of Triple-Effect Evaporators in Pharmaceuticals

The pharmaceutical industry is moving toward energy-efficient and sustainable manufacturing. With the dual pressures of cost reduction and environmental compliance, triple-effect evaporators are becoming indispensable. As heat pump integration and multi-effect evaporation technology advance, pharmaceutical companies can save energy while meeting stricter environmental standards. WTEYA integrates cutting-edge technologies into its evaporator systems, helping clients remain competitive while achieving global sustainability goals.

Conclusion:

Triple-effect evaporators are transforming pharmaceutical manufacturing by providing efficient, eco-friendly, and energy-saving solutions for liquid concentration and solvent recovery. By leveraging multi-stage evaporation and heat recovery, these systems reduce energy consumption, improve product quality, and minimize emissions. WTEYA’s expertise in designing and implementing these systems helps pharmaceutical companies optimize operations, reduce costs, and achieve sustainability goals. As the industry evolves, triple-effect evaporators will become key tools for ensuring high-quality products and supporting environmentally responsible practices.

Why Choose WTYEA?

WTYEA Is Recruiting Global Partners!

We welcome your partnership. As a brand with nearly 20 years of experience, WTEYA offers various preferential policies, professional training guidance, and comprehensive technical support you can rely on!

👉 Let WTYEA help you achieve unmatched water quality performance!