UF Ultra Filter System

Menu

Latest News

Product introduction

UF ultrafiltration water treatment syste mintroduction

UF system ultrafiltration water treatment machine is a device that uses the membrane separation technology for filtration water. It can remove impurities such as bacteria, glue in water.

UF (ultra-filtration) is a high-efficient technology that uses ultra-filtration precision films under 0,01 micron (one-percent mm) for cleaning water quality. This technique can allow the solution of water molecules and some small molecules to pass through the filtration membrane, while electrolytes like suspension agents, some colloids and creatures are stuck to achieve the purpose of purification. UF system usually includes parts such as rough water system, ultrafiltration host, cleaning system and dosing system, integration of these ingredients work together to remove water quality efficiently.

Component of ultrafiltration water treatment system

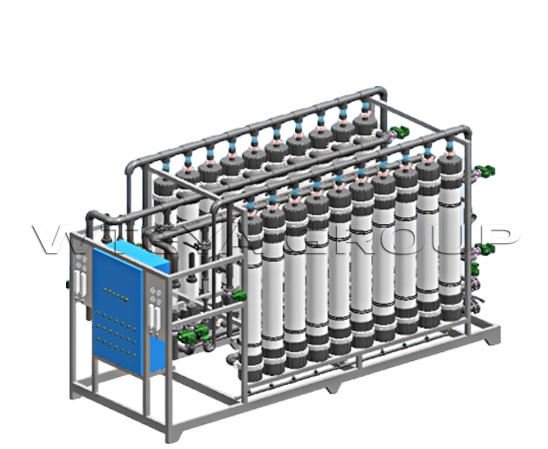

The UF system component is more complex, it include coarse liquid, water dispenser, water storage device, food pump, filtration liquid, bag Filter, hollow fiber ultrafiltration membrane, onsite tools, metering system, Full-auto control system, rack platform and other parts. Of them, the choice of pretreatment equipment is customized according to different rough water situations, popular pre-treatment devices include multimedia filter, security filter, and so on. To ensure water into the membrane component meets requirements and prevent Film pollution.

Feature of ultrafiltration water treatment system

High efficiency filtration ability: UF ultrafiltration system can effectively eliminate particles, colloids, bacteria, heat source and organic substances, supply high quality water production.

Energy saving: In general, the UF ultrafiltration equipment does not require the use of high-pressure pump when operate, therefore low energy consumption.

Easy and simple maintenance: due to the less joint and low water pressure, the gear failure rate and the relatively low water leakage rate, more convenient for maintenance.

Cost effective: the UF system is simple and inexpensive, no need for chemical reagent, useful for reducing operation cost.

In short, medium UF ultra-filtration membrane system has the advantages of high filtration precision, good hydrophobicity, high mechanical strength, strong chemical resistance and oxidation resistance, strong cleaning power and high response, Therefore, it is widely used in water treatment, beverage processing, waste water treatment and other areas.

Application field of ultrafiltration water treatment system

Drinking Water Treatment: ultrafiltration technology is used to remove suspended substances, organic substances, bacteria and virus from water to improve drinking water quality. Globally, the rate of use for drinking water treatment is about 60%.

Industrial water treatment: in large industrial areas, ultrafiltration technology used for industrial water treatment to eliminate impurities that may affect product quality, taken about 18%.

Reuse medium water, sewage water and sewage treatment: ultrafiltration technology also play a important role in reuse medium water and waste water treatment, help to reduce the environment pollution and improve the rate of water resources recycling, Takes about 15%.

Food, beverage and pharmaceutical industries: in these industries, ultrafiltration technology is used for sterilization, turbidity sterilization, endogen elimination and concentrate to ensure product purity and safety, Other light industries such as electronics, textiles, printing and dyeing, paper making, etc also accounted for a certain ratio, about 7%.

Sea salts filtration: ultrafiltration technology is also applied during the filtration process of marine water, which helps reduce salt and other impurities in sea water to reach fresh water sources.

Technical principle of

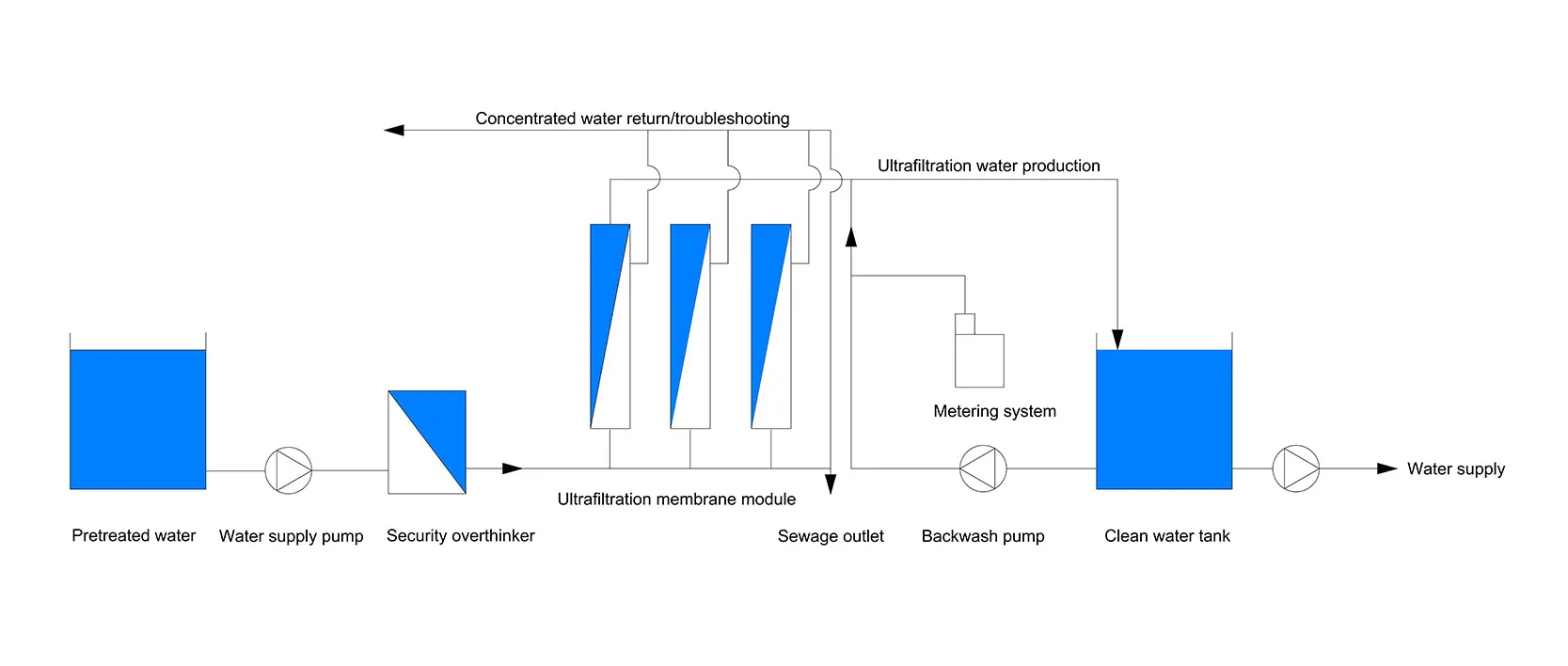

Ultrafiltration operation principle (UF) is mainly based on membrane separation technology, it is a physical separation process using semi-automatic membrane with a certain aperture as filtration media. Under the action of the external pressure, when the liquid compound flows through the ultrafiltration membrane, the water molecules are smaller than the membrane aperture, solvent molecular and some small molecular material can go through the membrane hole smoothly, While molecular materials are bigger than the film aperture, colloidal particles, creatures, pests, etc. Blocked at the top of the membrane, thereby achieved the purity, separation, or concentration of solution. The specific process is as follow:

Rough fluid transportation: treated fluid (such as water, solution or mud) is inserted by the inlet of Ultrafiltration System under certain pressure.

Separation process: when the material liquids are in contact with the ultrafiltration membrane, only components smaller than the membrane aperture are allowed to pass through due to the limit of the membrane aperture. For example, if the film aperture is 0,01-0,1 micron, then the water, ion and other small molecular materials can pass through, while bacteria, virus, large molecular organic agents, colloidal particles, etc. V. T. Blocked at one side of the membrane.

Through and trap: small molecular material through the film hole will form a osmosis liquid, which is ultrafiltration through liquid, usually more pure; meanwhile, The electrolytes left by the film are stored at the highest side of the film, become concentrate or called ultrafiltration fluid.

Cleaning and reborn: with additional operating time, the ultrafiltration membrane surface can have sedimentation, absorbency, and even scale, resulting in the loss of membrane flow, Thus it is required to regularly clean chemicals or backflow to revert the separation performance of the membrane.

The production process of

Production of equipment

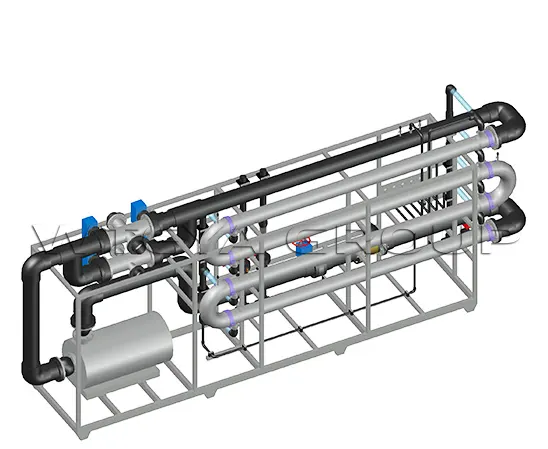

WTEYA aims to digital and intelligent production to provide superior products and services to its customers. We not only provide a wide range of standard products which are seriously tested and stable performance to meet a wide range of industrial needs. We also provide custom service, as well as OEM and ODM services, professional design team provides proper solutions for customers to meet their unique needs. We will work closely with each customer to ensure that every device suits customer's process requirements and production process accurately. WTEYA's one-stop service, innovative to create high-quality mechanical products and system solutions, professionally help customer deal with various water treatment problems.

Capacity and size

|

Ultrafiltration equipment parameter board |

||||

|

Cut out model |

Power rating of cloth |

Power of installation |

Main machine size |

The material is made of high quality |

|

WTY-UF-1 |

1000L/H |

1.0kw |

800 × 800 × 1500mm(H) |

304/ UPVC/ PVDF |

|

WTY-UF-2 |

2000L/H |

1.3kw |

1000 × 800 × 1500mm(H) |

|

|

WTY-UF-5 |

5000L/H |

3.7kw |

2000 × 1000 × 2200mm(H) |

|

|

WTY-UF-10 |

10000L/H |

6.4kw |

2000 × 1800 × 2200mm(H) |

|

|

WTY-UF-20 |

20000L/H |

18.5kw |

3600 × 2000 × 2600mm(H) |

|

Chart of effect chart

Frequently Asked Questions

Q: What particles of ultrafiltration film can remove?

Re: the ultrafiltration membrane can remove fine particles, suspended substances, some large molecular organic substances, bacteria and virus in water, but it will not be able to remove entirely small molecular substances like salt and sugar.

Q: How long life of ultrafiltration membrane?

Re: the lifetime of ultrafiltration membrane is affected by many factors, such as rough water quality, operating conditions, maintenance and maintenance, etc. V., usually can up to a few years. Frequent washing and maintenance can extend its life.

Q: How to deal with the pollution problem of ultrafiltration membrane?

Re: the pollution of ultrafiltration membrane can be processed by physical cleaning (such as pull or circulation washing) and chemical cleaning (specific chemical cleaners use).

Q: What kind of applications does the filtration system suit?

Re: the filtration system is suitable for many areas such as filtration water, waste water reuse, food and beverage, Biological Pharmaceutical, salt filtration pretreatment, etc. V. T.

Q: What parameters do you need to be noticed in the operation of the filtration system?

Re: the main parameters should be interested in Ultrafiltration System operation including the water pressure, water production, water quality status (such as turbidity and biological content) and the cross-film pressure difference, etc. V. T.

Q: Do filtration system need pre-treatment?

Re: in order to protect the ultrafiltration membrane and improve filtration efficiency, coarse water usually need to be pre-handled, including steps as suspension agent, adjust pH, soften.

Q: How about the energy consumption of Ultrafiltration System?

Re: the Ultrafiltration System has relatively low power consumption as it does not need high pressure pump to operate, but the specific energy consumption depends on the system design, scale and operating condition.

Q: Is Ultrafiltration System inexpensive for maintenance?

Re: compare to other film separation technology, the maintenance cost of Ultrafiltration System is lower, but still need to replace the film component regularly and maintain cleaning, the specific cost depends on the frequency of use and water quality condition.

Previous: Ultrafiltration Water Processor

Next: No More